Optimize 3D Printing: Balance and Efficiency

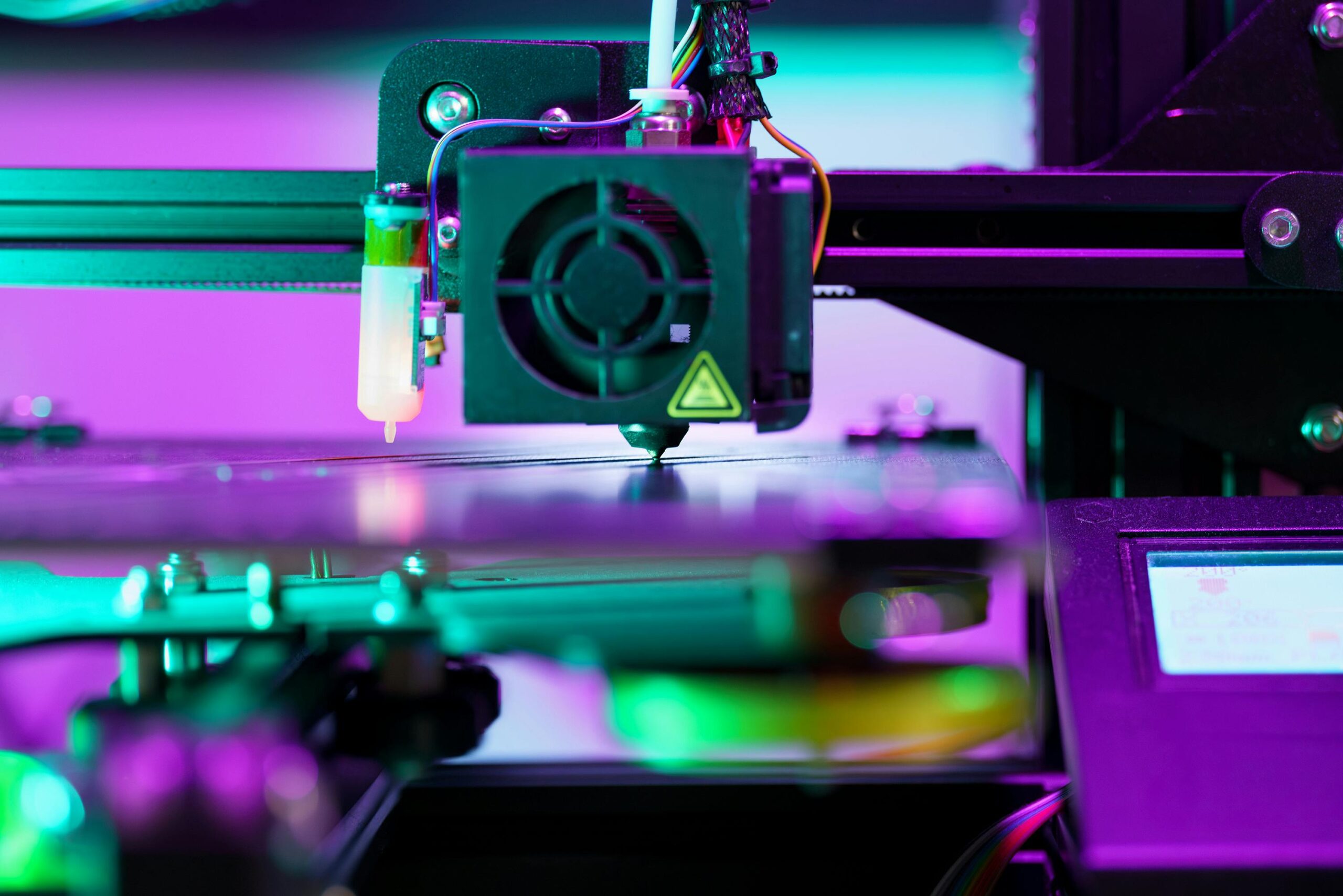

3D printing has transformed how we create objects, but finding the perfect balance between layer height, structural integrity, and production speed

3D printing has transformed how we create objects, but finding the perfect balance between layer height, structural integrity, and production speed

Durability testing has become the cornerstone of modern manufacturing, especially for low-energy parts that demand longevity without compromising efficiency or sustainability.

Hybrid printing is revolutionizing 3D manufacturing by combining thin outer shells with robust internal cores, delivering exceptional strength while reducing material

3D printing technologies are revolutionizing manufacturing by offering unprecedented design freedom while presenting distinct energy consumption profiles that directly impact operational

3D printing enthusiasts constantly seek the perfect balance between reducing material usage and maintaining structural integrity. Advanced slicing techniques now offer

In an era where sustainability meets productivity, understanding and managing your print energy consumption has become critical for businesses and individuals

Warping can ruin even the most promising 3D print, especially when working with low-temperature materials. Understanding heat dynamics is essential for

Selecting the right materials for durable performance while minimizing energy consumption is crucial for sustainable development and cost-effective operations across industries.

Advanced post-processing techniques have revolutionized how we achieve durable, long-lasting results across manufacturing, 3D printing, and industrial applications. In today’s competitive

Modern support structures demand a delicate balance between maintaining strength and optimizing resource allocation, challenging engineers to innovate without compromising safety