Boost Efficiency: Measure Print Energy

In an era where sustainability meets productivity, understanding and managing your print energy consumption has become critical for businesses and individuals

In an era where sustainability meets productivity, understanding and managing your print energy consumption has become critical for businesses and individuals

Warping can ruin even the most promising 3D print, especially when working with low-temperature materials. Understanding heat dynamics is essential for

Selecting the right materials for durable performance while minimizing energy consumption is crucial for sustainable development and cost-effective operations across industries.

Advanced post-processing techniques have revolutionized how we achieve durable, long-lasting results across manufacturing, 3D printing, and industrial applications. In today’s competitive

Modern support structures demand a delicate balance between maintaining strength and optimizing resource allocation, challenging engineers to innovate without compromising safety

3D printing technology has revolutionized manufacturing, but its environmental impact demands attention. Sustainable filaments and eco-friendly resins are transforming how we

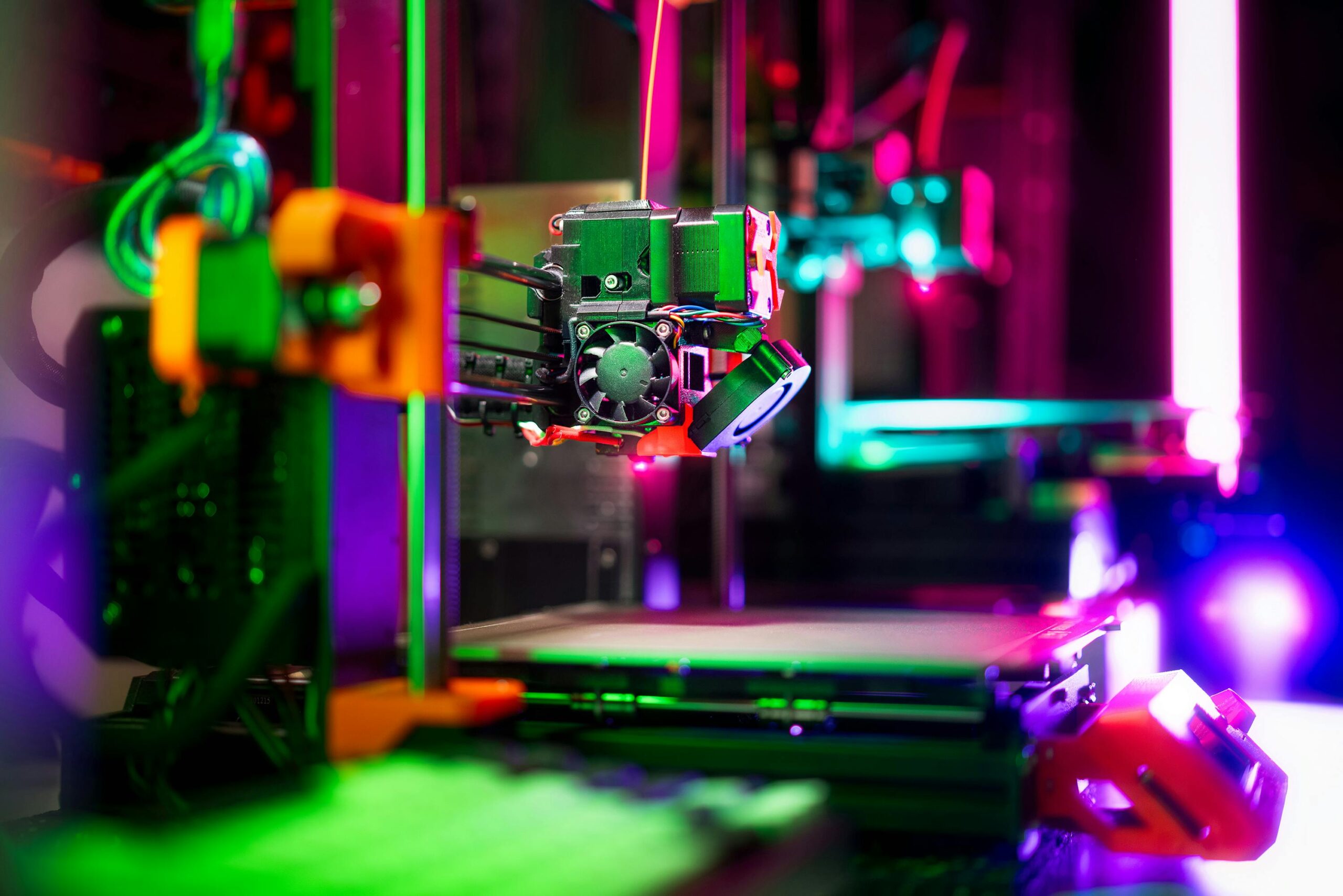

3D printing success hinges on precise calibration. Mastering these essential routines transforms frustrating failures into consistent, high-quality prints while saving time

3D printing technology is transforming how we think about manufacturing, offering unprecedented opportunities to reduce waste, lower carbon emissions, and create

Sustainable design in print isn’t just an environmental trend—it’s a strategic approach that reduces waste, cuts costs, and demonstrates corporate responsibility

Printing costs silently drain business budgets, but batch printing technology offers a powerful solution to reduce energy consumption and operational expenses