The 3D printing industry has exploded in popularity, often marketed as the ultimate eco-friendly manufacturing solution. But beneath the surface of sustainability claims lies a disturbing trend of greenwashing that consumers and businesses must learn to identify.

🔍 The Green Promise of 3D Printing: Separating Fact from Fiction

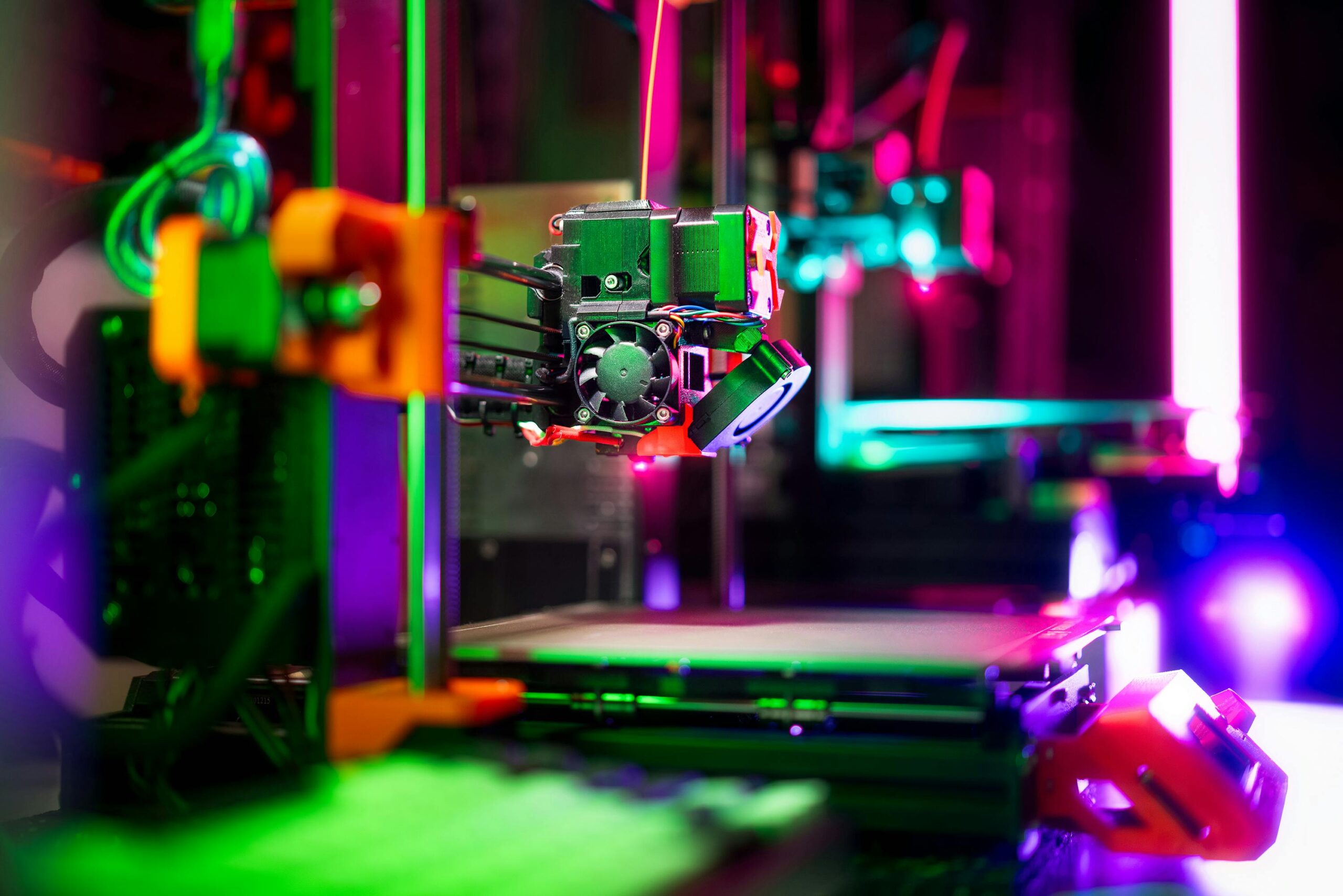

Three-dimensional printing technology has been heralded as a revolutionary approach to sustainable manufacturing. Companies tout reduced waste, localized production, and biodegradable materials as the cornerstones of an environmentally responsible future. While some of these claims hold merit, the reality is considerably more complex than marketing materials suggest.

The additive manufacturing process does offer genuine advantages over traditional subtractive methods. Instead of cutting away material from a larger block, 3D printers build objects layer by layer, theoretically minimizing waste. This fundamental difference has become the foundation for countless sustainability claims across the industry.

However, this simplified narrative conveniently ignores the complete lifecycle environmental impact of 3D printing. From raw material extraction and processing to energy consumption during printing and eventual disposal, the full picture reveals nuances that greenwashing campaigns deliberately obscure.

🎭 Common Greenwashing Tactics in the 3D Printing Industry

Understanding how companies manipulate environmental narratives is crucial for making informed decisions. The 3D printing sector employs several deceptive strategies that deserve scrutiny.

The Biodegradable Material Myth

Perhaps the most widespread deceptive claim involves biodegradable filaments, particularly PLA (Polylactic Acid). Manufacturers heavily promote PLA as an eco-friendly alternative derived from renewable resources like corn starch. While technically accurate, this narrative omits critical information about its actual environmental performance.

PLA requires specific industrial composting conditions to break down effectively. Temperature, humidity, and microbial presence must align perfectly for decomposition to occur within a reasonable timeframe. In typical landfill conditions or natural environments, PLA persists for years, functioning essentially as conventional plastic.

Companies rarely disclose that industrial composting facilities capable of processing PLA remain scarce in most regions. This accessibility gap transforms the “biodegradable” claim from a practical environmental benefit into a misleading technicality.

Selective Energy Consumption Reporting

Another common greenwashing tactic involves cherry-picking energy consumption data. Marketing materials frequently compare the energy used during the actual printing process against traditional manufacturing, conveniently excluding the broader energy footprint.

The complete energy picture includes material production, printer manufacturing, transportation, failed prints requiring reprinting, post-processing treatments, and disposal. When these factors are accounted for, the energy advantage of 3D printing becomes significantly less impressive, particularly for small-scale operations.

The “Zero Waste” Exaggeration

The claim that 3D printing produces zero waste ranks among the most misleading assertions in the industry. While additive manufacturing reduces material waste during the building process, it generates waste through multiple other channels.

Support structures required for complex geometries often constitute 20-40% of total material used and typically end up in the trash. Failed prints, rafts, brims, and purge towers add to the waste stream. Packaging materials, worn-out nozzles, build plates, and obsolete equipment further contradict the zero-waste narrative.

🧪 The Hidden Environmental Costs Nobody Discusses

Beyond the obvious greenwashing tactics, several environmental impacts receive minimal attention in marketing campaigns yet significantly affect the technology’s true sustainability profile.

Volatile Organic Compounds and Indoor Air Quality

Desktop 3D printers operating in homes, schools, and offices emit ultrafine particles and volatile organic compounds during operation. Research has documented emissions of styrene, caprolactam, and other potentially harmful chemicals, particularly when printing with ABS and similar materials.

Companies downplay or ignore these air quality concerns in their sustainability messaging. The focus remains on recyclability and renewable materials while the immediate health and environmental impacts of operation receive minimal disclosure.

Microplastic Generation

The 3D printing process generates microplastics through several mechanisms: abrasion during printing, degradation of printed objects over time, and breakdown of improperly disposed items. These microscopic particles enter ecosystems and water systems, contributing to a growing environmental crisis that greenwashing campaigns conveniently overlook.

The E-Waste Problem

Consumer 3D printers have limited lifespans, often becoming obsolete within 3-5 years due to technological advancement or mechanical failure. The electronics, motors, circuit boards, and other components contribute to the global e-waste crisis.

Marketing materials rarely address end-of-life considerations for the printers themselves, focusing instead on the recyclability of printed objects. This selective disclosure paints an incomplete sustainability picture.

🔎 Red Flags: How to Identify 3D Printing Greenwashing

Developing critical evaluation skills helps consumers and businesses navigate misleading environmental claims. Watch for these warning signs when assessing sustainability assertions.

Vague or Unquantified Claims

Terms like “eco-friendly,” “green,” “sustainable,” and “environmentally conscious” without supporting data indicate potential greenwashing. Legitimate environmental benefits can be measured and should be presented with specific metrics.

Ask for concrete numbers: How much energy does the process consume? What percentage of material is actually recyclable in practice? What is the documented decomposition rate under specified conditions?

Misleading Imagery and Associations

Green color schemes, nature imagery, and leaf logos create environmental associations without substantive backing. These visual cues trigger positive emotional responses while providing zero factual information about actual environmental performance.

Narrow Focus on Single Attributes

Companies highlighting one positive environmental aspect while ignoring the broader impact engage in greenwashing. A material might be renewable but require enormous processing energy. A process might reduce production waste but generate toxic emissions.

Comprehensive sustainability assessment considers the entire lifecycle, from raw material extraction through disposal. Single-attribute claims almost always tell an incomplete story.

Absence of Third-Party Verification

Self-declared environmental claims lack credibility without independent verification. Legitimate certifications from recognized organizations like ISO, GreenGuard, or Cradle to Cradle provide external validation of environmental performance.

Be skeptical of proprietary “eco-certifications” or internal sustainability ratings without transparent methodology and external auditing.

✅ Making Genuinely Sustainable 3D Printing Choices

Despite widespread greenwashing, pathways exist for more environmentally responsible 3D printing practices. Informed consumers can make choices that align with genuine sustainability principles.

Material Selection Strategies

Choose materials based on complete lifecycle assessment rather than marketing claims. Research actual disposal options in your area before purchasing “biodegradable” filaments. Consider recycled filament options from reputable suppliers who transparently document their recycling processes.

Investigate closed-loop systems where failed prints and support material can be reprocessed into usable filament. These circular approaches offer more tangible environmental benefits than theoretical biodegradability.

Operational Best Practices

Maximize print success rates through proper calibration and maintenance, reducing wasted material from failed attempts. Optimize support structure settings to minimize removable material. Design parts with sustainability in mind, considering strength-to-material ratios and end-of-life disassembly.

Operate printers in well-ventilated spaces to minimize indoor air quality impacts. Consider enclosures with filtration systems for materials known to emit higher levels of volatile compounds.

Equipment Longevity and Responsibility

Invest in repairable, upgradeable equipment rather than disposable consumer models. Choose manufacturers committed to providing replacement parts and supporting equipment beyond typical product cycles.

When equipment reaches end-of-life, utilize proper e-waste recycling channels rather than landfill disposal. Some manufacturers offer take-back programs for responsible recycling.

🎯 Questions to Ask Before Believing Environmental Claims

Developing a critical evaluation framework helps cut through marketing noise and identify genuine sustainability efforts. Apply these questions to any environmental claim encountered in 3D printing marketing.

- What specific, measurable environmental benefit does this claim assert?

- Has this claim been verified by independent third-party organizations?

- Does the claim consider the complete lifecycle or only a single stage?

- Are disposal requirements and end-of-life options clearly explained?

- What negative environmental impacts are not mentioned?

- Can I access transparent data supporting this environmental claim?

- Does the company provide detailed sustainability reporting beyond marketing materials?

- Are there realistic, accessible pathways to achieve the claimed environmental benefits?

📊 The Real Environmental Performance Scorecard

Understanding actual environmental performance requires examining multiple factors simultaneously. This balanced assessment reveals where 3D printing genuinely excels and where marketing claims outpace reality.

| Environmental Factor | Marketing Claim | Reality Check |

|---|---|---|

| Material Waste | Zero waste production | Reduced production waste, but significant waste from supports, failures, and packaging |

| Energy Consumption | Low energy manufacturing | Variable depending on scale; often higher than claimed when including full lifecycle |

| Biodegradability | Eco-friendly decomposition | Requires specific industrial conditions rarely available; persists in typical environments |

| Recycling | Fully recyclable materials | Limited recycling infrastructure; contamination issues; quality degradation |

| Local Production | Eliminates shipping impacts | True benefit but often overstated; raw materials still require transportation |

🌱 The Future of Honest Sustainability in 3D Printing

The path forward requires industry-wide commitment to transparency and accountability. Several developments signal potential progress toward more honest environmental communication.

Emerging Standards and Certifications

Organizations are developing comprehensive sustainability standards specific to additive manufacturing. These frameworks assess environmental impact across multiple dimensions rather than focusing on isolated attributes.

Support for these standardization efforts encourages broader adoption and creates clearer benchmarks for comparing environmental performance claims.

Consumer Awareness and Demand

Educated consumers increasingly question vague environmental claims and demand substantiation. This market pressure incentivizes companies to back sustainability assertions with verifiable data or risk reputation damage.

Supporting businesses that provide transparent, comprehensive environmental information sends clear market signals about consumer priorities.

Technological Innovations with Genuine Impact

Research into truly compostable materials, closed-loop recycling systems, and lower-emission printing processes offers hope for substantive environmental improvements. These innovations require time, investment, and validation before reaching mainstream adoption.

Realistic expectations about the timeline and limitations of these technologies prevent premature celebration while supporting their continued development.

💡 Taking Action Against Greenwashing

Individual awareness represents the first step, but collective action amplifies impact. Several strategies help combat deceptive environmental marketing throughout the 3D printing industry.

Challenge unsubstantiated claims directly with manufacturers and retailers. Request specific data and third-party verification. Companies responsive to these inquiries demonstrate commitment to transparency, while dismissive responses reveal priorities.

Share knowledge within maker communities, educational institutions, and professional networks. Peer education multiplies the impact of individual research and creates cultural expectations for environmental honesty.

Support regulatory efforts to establish clear guidelines for environmental marketing claims. Contact elected representatives about concerns regarding greenwashing across industries, including additive manufacturing.

Document and report deliberately misleading environmental claims to consumer protection agencies and advertising standards organizations. These bodies rely on consumer reports to identify and address deceptive marketing practices.

🎓 Building Environmental Literacy in the Maker Community

The maker movement embraces innovation, experimentation, and knowledge sharing. Applying these same principles to environmental literacy strengthens the entire community’s ability to recognize and resist greenwashing.

Educational institutions integrating 3D printing into curricula should include critical evaluation of environmental claims as part of technology instruction. Students learning to operate printers should simultaneously learn to assess sustainability assertions critically.

Online communities, forums, and maker spaces can facilitate information exchange about actual environmental performance. Crowdsourced testing and documentation provide alternatives to manufacturer marketing materials.

Transparent sharing of both successes and failures in sustainable 3D printing practices benefits everyone. Honest discussion about challenges prevents unrealistic expectations while identifying genuinely effective approaches.

🔬 The Role of Independent Research and Testing

Academic institutions and independent research organizations provide crucial counterbalances to industry marketing. Peer-reviewed studies examining lifecycle impacts, emissions profiles, and actual disposal outcomes offer evidence-based alternatives to promotional claims.

Supporting and amplifying this research helps ground public understanding in facts rather than marketing narratives. Following recent publications in additive manufacturing and environmental science journals reveals evolving understanding of true environmental impacts.

When companies cite research supporting environmental claims, verify that studies are peer-reviewed, conducted by independent researchers, and actually support the specific claims being made. Misrepresentation of research findings constitutes a common greenwashing tactic.

🌍 The Bigger Picture: 3D Printing in Context

Ultimately, evaluating 3D printing sustainability requires comparing it appropriately to alternatives within specific contexts. The technology excels in certain applications while offering minimal or negative environmental benefit in others.

For rapid prototyping, small-batch production, and customized medical devices, 3D printing may offer genuine environmental advantages over traditional manufacturing approaches. For mass production of simple objects, conventional methods often demonstrate superior environmental performance.

Honest assessment acknowledges these nuances rather than promoting 3D printing as universally sustainable solution. Context-specific evaluation enables appropriate technology selection based on actual rather than claimed environmental impact.

The conversation surrounding 3D printing and sustainability must mature beyond simplistic narratives. Embracing complexity, demanding transparency, and maintaining critical perspective protects against greenwashing while supporting genuinely beneficial environmental innovations. The technology holds real potential for positive environmental impact, but realizing that potential requires honest assessment of current limitations and commitment to meaningful improvement rather than superficial marketing.

Toni Santos is a materials researcher and sustainable manufacturing specialist focusing on the development of next-generation biopolymer systems, renewable feedstock cultivation, and the practical innovations driving resource-efficient additive manufacturing. Through an interdisciplinary and science-driven approach, Toni investigates how natural organisms can be transformed into functional materials — across filament chemistry, bio-based composites, and closed-loop production systems. His work is grounded in a fascination with algae not only as lifeforms, but as carriers of industrial potential. From algae filament research to bio-resin development and durable low-energy prints, Toni uncovers the material and engineering pathways through which sustainable practices reshape the future of digital fabrication. With a background in material science and sustainable manufacturing, Toni blends polymer analysis with renewable biomass research to reveal how natural resources can be harnessed to reduce carbon footprint, improve durability, and enable circular production. As the creative mind behind Veltrynox, Toni curates biofilament innovations, low-impact printing methods, and material strategies that advance the ecological integration of 3D printing, biopolymers, and renewable manufacturing systems. His work is a tribute to: The renewable potential of Algae Filament Research and Cultivation The transformative chemistry of Bio-Resin Development and Biocomposites The engineering resilience of Durable Low-Energy Print Systems The sustainable future of Eco-Friendly 3D Printing and Green Manufacturing Whether you're a materials innovator, sustainability engineer, or curious explorer of renewable manufacturing, Toni invites you to discover the transformative power of bio-based materials — one layer, one filament, one sustainable print at a time.