3D printing is revolutionizing manufacturing, but its true environmental impact remains a complex puzzle that lifecycle assessment is finally helping us solve. 🌱

The intersection of additive manufacturing and environmental sustainability has emerged as one of the most critical conversations in modern production. As 3D printing technology becomes increasingly accessible and widespread, understanding its ecological footprint through comprehensive lifecycle assessment (LCA) has never been more important. This methodology offers unprecedented insights into how these innovative manufacturing processes truly affect our planet, from raw material extraction to end-of-life disposal.

Understanding Lifecycle Assessment in the Context of 3D Printing

Lifecycle assessment represents a systematic approach to evaluating the environmental impacts of a product throughout its entire existence. When applied to 3D printed products, this methodology examines every stage: raw material sourcing, manufacturing processes, transportation, usage phase, and eventual disposal or recycling. Unlike traditional assessment methods that might focus on a single aspect of production, LCA provides a holistic view that captures the complete environmental narrative.

For 3D printed products specifically, lifecycle assessment reveals surprising insights that often challenge conventional wisdom about sustainable manufacturing. The technology’s reputation as inherently “green” doesn’t always align with reality when subjected to rigorous scientific scrutiny. Understanding these nuances helps manufacturers, designers, and consumers make truly informed decisions about when and how to implement additive manufacturing for maximum environmental benefit.

The Four Critical Phases of 3D Printing LCA

Material extraction and processing forms the foundation of any product’s environmental story. In 3D printing, this phase includes mining raw materials for plastics, metals, or ceramics, refining them into printable filaments or powders, and transporting these materials to manufacturing facilities. Different printing materials carry vastly different environmental burdens during this initial stage.

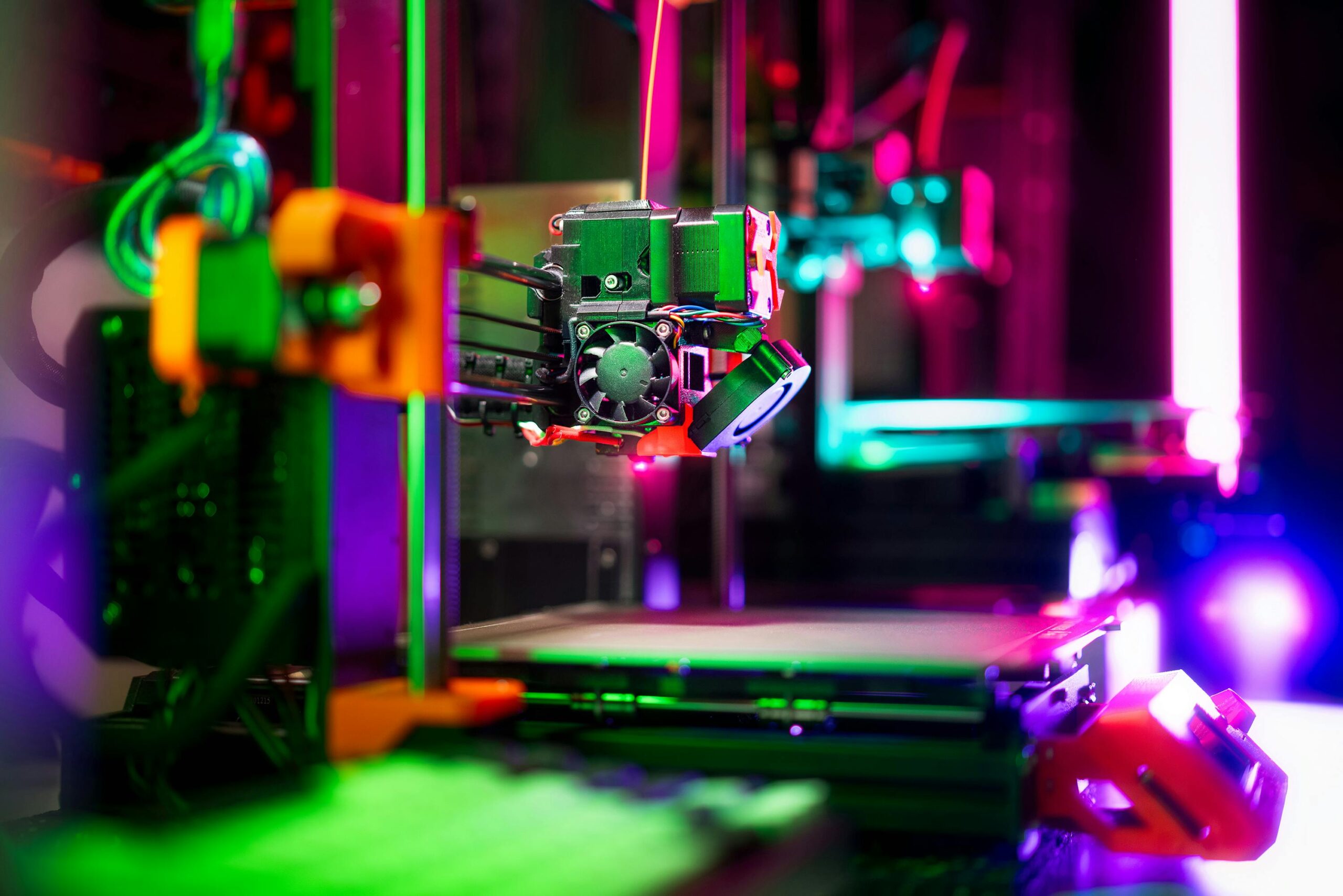

The manufacturing phase encompasses the actual printing process, including energy consumption during printing, material waste from supports and failed prints, and the environmental controls required for optimal printing conditions. Modern 3D printers vary dramatically in their energy efficiency, with some industrial machines consuming significant electricity while desktop units operate on modest power requirements.

Distribution and use phases often favor 3D printing over traditional manufacturing. Localized production reduces transportation emissions, while the ability to create lightweight, optimized designs can decrease energy consumption during a product’s useful life. This advantage becomes particularly pronounced for applications like aerospace components or automotive parts where weight reduction directly translates to fuel savings.

End-of-life considerations complete the lifecycle picture. The recyclability of 3D printed materials, potential for product repair through printing replacement parts, and biodegradability of certain filaments all contribute to the overall environmental equation. This phase often reveals opportunities for circular economy integration that traditional manufacturing struggles to achieve.

Material Matters: Comparing Environmental Footprints Across Filament Types

Polylactic acid (PLA) has emerged as a favorite among environmentally conscious makers due to its plant-based origins. Derived from renewable resources like corn starch or sugarcane, PLA offers biodegradability under industrial composting conditions. However, lifecycle assessment reveals that PLA production still requires significant agricultural inputs, including water, fertilizers, and land use that might otherwise support food crops or natural ecosystems.

Petroleum-based plastics like ABS and PETG present a different environmental profile. While derived from non-renewable fossil fuels, these materials often demonstrate superior mechanical properties that extend product lifespan. LCA studies show that durability can sometimes outweigh the benefits of bio-based materials when products require frequent replacement. The recyclability of these conventional plastics also factors into their overall environmental equation.

Metal and Advanced Materials: A Complex Environmental Story 🔩

Metal 3D printing for titanium, aluminum, and steel components typically requires substantial energy inputs during both material production and the printing process itself. However, the technology’s ability to create topology-optimized designs that use 30-50% less material than traditional manufacturing can offset these initial environmental costs. Aerospace applications particularly benefit from this trade-off, where lighter components yield fuel savings that compound over a product’s operational lifetime.

Composite materials and experimental bio-based filaments continue expanding the environmental possibilities of additive manufacturing. Materials incorporating wood fibers, algae-based polymers, or recycled ocean plastics demonstrate how 3D printing can integrate circular economy principles directly into the manufacturing process. Lifecycle assessments of these innovative materials help separate genuine environmental progress from greenwashing marketing claims.

Energy Consumption: The Hidden Environmental Cost

The electricity required to power 3D printers varies enormously across technologies and machine types. Fused deposition modeling (FDM) printers typically consume between 50-200 watts during operation, comparable to a laptop computer. In contrast, industrial selective laser sintering (SLS) or direct metal laser sintering (DMLS) machines can draw several kilowatts, approaching the energy demands of traditional CNC machining centers.

Print duration significantly impacts total energy consumption. A small desktop component might complete in two hours, while large industrial parts can require days of continuous printing. Lifecycle assessment must account for these temporal factors alongside the power draw specifications. Optimizing print settings for speed versus quality directly influences the environmental footprint of each manufactured item.

The Geographic Factor in Energy Impact

Where you print matters as much as how you print. A 3D printer powered by renewable energy sources like solar or wind carries a dramatically different environmental burden than one operating on coal-generated electricity. Lifecycle assessments increasingly incorporate regional energy grid compositions to provide location-specific environmental impact data. This geographic nuance helps businesses make strategically sound decisions about where to locate additive manufacturing facilities.

Time-of-use considerations add another layer of complexity. Some manufacturers schedule energy-intensive prints during off-peak hours when grid electricity comes predominantly from renewable sources. This temporal optimization represents an emerging strategy for minimizing the carbon footprint of 3D printed products without sacrificing production capacity or quality.

Waste Reduction: Where 3D Printing Truly Shines ♻️

Traditional subtractive manufacturing often wastes 40-90% of raw materials through cutting, drilling, and milling processes. Aerospace aluminum components famously exemplify this inefficiency, with buy-to-fly ratios sometimes exceeding 10:1. Additive manufacturing fundamentally changes this equation by depositing material only where needed, theoretically achieving near-zero material waste.

Reality introduces complications to this idealized scenario. Support structures required for overhanging features add material usage that doesn’t contribute to the final product. Failed prints due to warping, adhesion issues, or machine malfunctions create waste that lifecycle assessments must acknowledge. However, even accounting for these practical challenges, 3D printing typically achieves material utilization rates above 90%, dramatically outperforming conventional manufacturing methods.

Recycling and Circular Economy Integration

The ability to recycle failed prints and support structures back into usable filament closes the loop in additive manufacturing. Desktop filament extruders now enable small-scale recycling operations, while industrial facilities implement comprehensive material recovery systems. Lifecycle assessments that incorporate these recycling capabilities reveal significantly improved environmental profiles compared to linear manufacturing models.

On-demand manufacturing enabled by 3D printing eliminates inventory waste from overproduction. Traditional manufacturing economics favor large production runs, often resulting in unsold inventory that eventually reaches landfills. Additive manufacturing’s economic viability at low volumes enables true just-in-time production, manufacturing products only when customers actually need them. This systemic waste reduction represents one of the technology’s most profound environmental contributions.

Transportation and Distributed Manufacturing

Globalized supply chains carry hidden environmental costs that lifecycle assessment quantifies through transportation impact categories. A product manufactured in Asia, shipped to North America, and distributed to consumers accumulates substantial carbon emissions before ever reaching its intended use. 3D printing enables localized manufacturing that dramatically compresses these supply chains.

Digital inventory represents a paradigm shift with profound environmental implications. Instead of warehousing physical products and shipping them worldwide, companies can store digital files and manufacture products near their point of consumption. This distributed manufacturing model reduces transportation emissions while simultaneously improving delivery times and reducing inventory carrying costs.

Spare Parts and the Right to Repair Movement

Product longevity significantly influences lifecycle environmental impact. The ability to 3D print replacement parts for broken products extends their useful life and delays disposal. From household appliances to agricultural equipment, additive manufacturing enables repair scenarios that traditional supply chains cannot economically support. This capability aligns perfectly with circular economy principles and right-to-repair advocacy.

Obsolescence resistance through printable parts means products don’t become trash simply because a manufacturer discontinued a specific component. Historical objects, vintage vehicles, and legacy industrial equipment all benefit from 3D printing’s ability to recreate parts that no longer exist in conventional supply chains. The environmental value of preventing premature disposal multiplies across millions of products worldwide.

Comparative Lifecycle Assessment: 3D Printing vs. Traditional Manufacturing

Context determines whether additive manufacturing offers environmental advantages over conventional methods. For complex geometries in small production volumes, 3D printing typically demonstrates superior environmental performance. The elimination of tooling requirements, reduced material waste, and design optimization capabilities combine to create compelling ecological benefits in these scenarios.

High-volume production of simple geometries often favors traditional manufacturing from a lifecycle perspective. Injection molding, for instance, amortizes its tooling and setup costs across thousands or millions of units, achieving per-unit environmental impacts that additive manufacturing struggles to match. Honest lifecycle assessment acknowledges these limitations rather than promoting 3D printing as universally superior.

The Break-Even Analysis Framework

Determining the production volume at which traditional manufacturing becomes more environmentally efficient than 3D printing requires detailed lifecycle modeling. Variables include part complexity, material type, transportation distances, energy sources, and end-of-life scenarios. Published LCA studies suggest break-even points typically occur between 100 and 10,000 units, depending on these factors.

Design complexity significantly shifts this break-even calculation. As part geometry increases in intricacy, 3D printing maintains consistent environmental impact while traditional manufacturing requires additional processing steps, specialized tooling, and increased waste. For highly complex components, additive manufacturing may remain environmentally preferable even at relatively high production volumes.

Future Horizons: Emerging Technologies and Environmental Innovation 🚀

Bio-based resins and filaments continue advancing toward truly sustainable additive manufacturing. Researchers are developing printable materials from algae, mycelium, and agricultural waste that offer genuine biodegradability without compromising mechanical performance. Lifecycle assessments of these next-generation materials will determine whether they deliver on their environmental promises or simply shift impacts to different categories.

Solar-powered 3D printing represents an emerging approach to eliminating operational carbon emissions entirely. Several organizations have demonstrated mobile 3D printing units powered by photovoltaic panels, enabling completely off-grid manufacturing in remote locations. As this technology matures, lifecycle assessments will reveal how effectively it addresses the energy consumption challenges that currently limit additive manufacturing’s environmental credentials.

Artificial Intelligence and Print Optimization

Machine learning algorithms increasingly optimize print parameters to minimize material usage and energy consumption while maintaining quality standards. These AI-driven approaches analyze thousands of variables simultaneously, identifying efficiency improvements that human operators might miss. Early lifecycle assessments of AI-optimized printing suggest environmental impact reductions of 15-30% compared to standard printing profiles.

Predictive maintenance powered by artificial intelligence reduces waste from failed prints and extends equipment lifespan. By identifying potential machine issues before they cause print failures, these systems prevent the material and energy waste associated with unsuccessful manufacturing attempts. The cumulative environmental benefit across millions of 3D printers worldwide could prove substantial as these technologies achieve widespread adoption.

Implementing Lifecycle Thinking in Your 3D Printing Practice

Material selection represents the most immediate opportunity for environmental impact reduction. Choosing appropriate materials for each application—using PLA for non-structural components, recycled PETG where durability matters, and metals only when truly necessary—optimizes the lifecycle environmental profile of your manufactured products.

Print setting optimization balances quality requirements against environmental considerations. Reducing infill density where structural requirements permit, eliminating unnecessary support structures through strategic part orientation, and combining multiple components in single print jobs all contribute to improved lifecycle performance without sacrificing functional requirements.

Energy awareness transforms how you approach manufacturing scheduling. Understanding your local electricity grid’s renewable energy percentage at different times enables strategic scheduling of energy-intensive prints during periods of cleaner power generation. This operational adjustment requires minimal effort while delivering measurable environmental benefits.

End-of-life planning should inform design decisions from the beginning. Considering how products will be disposed, recycled, or composted influences material selection and design features. Building products that facilitate disassembly and material separation enables more effective recycling and reduces the environmental burden of eventual disposal.

The Path Forward: Balancing Innovation and Environmental Responsibility 🌍

Lifecycle assessment provides the scientific foundation for environmentally responsible 3D printing adoption. As the technology continues evolving and expanding into new applications, rigorous environmental evaluation ensures we harness its genuine sustainability benefits while acknowledging and addressing its limitations. The most successful implementations will be those that approach additive manufacturing not as an automatically “green” technology but as a powerful tool that requires thoughtful application.

The eco-friendly evolution of 3D printing ultimately depends on collective commitment to transparency, continuous improvement, and honest assessment of environmental impacts across the complete product lifecycle. By embracing lifecycle thinking, the additive manufacturing community can guide this transformative technology toward its full potential as a cornerstone of sustainable production in the decades ahead.

Toni Santos is a materials researcher and sustainable manufacturing specialist focusing on the development of next-generation biopolymer systems, renewable feedstock cultivation, and the practical innovations driving resource-efficient additive manufacturing. Through an interdisciplinary and science-driven approach, Toni investigates how natural organisms can be transformed into functional materials — across filament chemistry, bio-based composites, and closed-loop production systems. His work is grounded in a fascination with algae not only as lifeforms, but as carriers of industrial potential. From algae filament research to bio-resin development and durable low-energy prints, Toni uncovers the material and engineering pathways through which sustainable practices reshape the future of digital fabrication. With a background in material science and sustainable manufacturing, Toni blends polymer analysis with renewable biomass research to reveal how natural resources can be harnessed to reduce carbon footprint, improve durability, and enable circular production. As the creative mind behind Veltrynox, Toni curates biofilament innovations, low-impact printing methods, and material strategies that advance the ecological integration of 3D printing, biopolymers, and renewable manufacturing systems. His work is a tribute to: The renewable potential of Algae Filament Research and Cultivation The transformative chemistry of Bio-Resin Development and Biocomposites The engineering resilience of Durable Low-Energy Print Systems The sustainable future of Eco-Friendly 3D Printing and Green Manufacturing Whether you're a materials innovator, sustainability engineer, or curious explorer of renewable manufacturing, Toni invites you to discover the transformative power of bio-based materials — one layer, one filament, one sustainable print at a time.