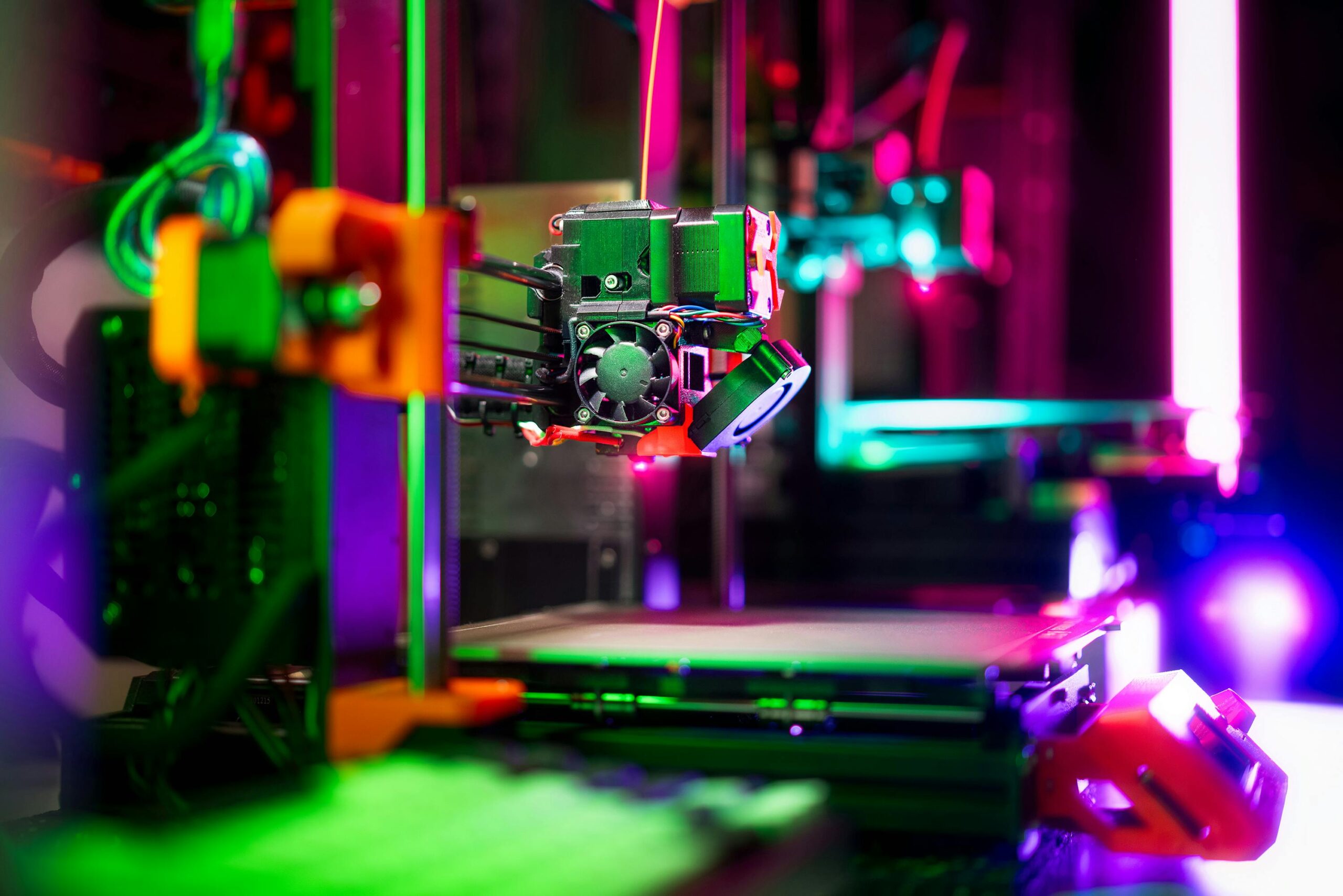

3D printing technology is transforming how we think about manufacturing, offering unprecedented opportunities to reduce waste, lower carbon emissions, and create a more sustainable industrial future.

🌱 The Green Revolution in Additive Manufacturing

Traditional manufacturing has long been synonymous with environmental degradation. Factories spewing emissions, mountains of waste material, and energy-intensive production processes have characterized industrial development for centuries. But 3D printing—also known as additive manufacturing—is rewriting this narrative in remarkable ways.

Unlike conventional subtractive manufacturing, which carves products from larger blocks of material and discards the excess, 3D printing builds objects layer by layer using only the material needed. This fundamental difference creates a cascade of environmental benefits that are becoming increasingly important as industries face mounting pressure to reduce their ecological footprint.

The technology has evolved dramatically since its inception in the 1980s. What began as a tool for rapid prototyping has matured into a viable production method across industries from aerospace to healthcare, from fashion to construction. And with each advancement, the environmental case for 3D printing grows stronger.

🔄 Minimizing Material Waste: The Core Advantage

The most immediate environmental benefit of 3D printing lies in its approach to material usage. Traditional manufacturing methods can waste up to 90% of raw materials in some industries, particularly in aerospace and automotive sectors where components are machined from solid blocks of metal or composite materials.

With additive manufacturing, waste reduction is built into the process itself. The printer deposits material precisely where needed, creating complex geometries without generating significant scrap. This efficiency translates directly into environmental benefits:

- Reduced extraction of raw materials from the earth

- Lower energy consumption in material processing

- Decreased transportation costs for raw materials

- Minimal waste requiring disposal or recycling

- Conservation of precious and rare earth materials

Studies have shown that 3D printing can reduce material waste by 70-90% compared to traditional machining processes. For industries consuming thousands of tons of materials annually, this represents both substantial cost savings and dramatic environmental improvements.

⚡ Energy Efficiency Across the Production Chain

The energy story of 3D printing is nuanced but generally positive. While the printing process itself can be energy-intensive, the overall lifecycle energy consumption often proves lower than traditional manufacturing when we consider the complete picture.

Manufacturing a product traditionally involves multiple steps: extraction, refinement, transportation, machining, assembly, and distribution. Each step consumes energy and generates emissions. 3D printing consolidates many of these steps, enabling production closer to the point of use and often eliminating assembly requirements entirely.

Desktop 3D printers typically consume between 50 and 100 watts during operation—roughly equivalent to a laptop computer. Industrial systems require more power, but their efficiency gains come from eliminating energy-intensive machining, reducing transportation needs, and enabling on-demand production that eliminates warehousing energy costs.

Localized Production: A Game-Changer for Carbon Footprints

Perhaps the most transformative environmental aspect of 3D printing is its potential to decentralize manufacturing. When products can be printed on-demand near their point of use, the environmental costs of global supply chains diminish dramatically.

Consider the journey of a traditionally manufactured plastic component: raw materials mined in one country, refined in another, molded in a third, assembled in a fourth, and finally shipped worldwide to consumers. Each step involves transportation—often by carbon-intensive methods like container ships and trucks.

With 3D printing, a digital file travels instantaneously via the internet, and the product is manufactured locally. This shift eliminates much of the transportation burden, reducing carbon emissions, packaging waste, and the environmental costs associated with maintaining complex global logistics networks.

♻️ Sustainable Materials Leading the Way

The environmental promise of 3D printing extends beyond the process to the materials themselves. The industry has witnessed explosive growth in sustainable, bio-based, and recycled printing materials that further enhance the technology’s green credentials.

PLA (polylactic acid), derived from renewable resources like corn starch and sugarcane, has become one of the most popular 3D printing materials. Unlike petroleum-based plastics, PLA is biodegradable under industrial composting conditions and comes from annually renewable crops rather than finite fossil fuels.

Innovation in sustainable filaments continues at a rapid pace. Manufacturers now offer materials incorporating:

- Recycled ocean plastics and post-consumer waste

- Wood fibers and sawdust from lumber operations

- Algae-based biopolymers that sequester carbon

- Hemp, bamboo, and other fast-growing plant fibers

- Recycled carbon fiber from retired aerospace components

Metal 3D printing has also embraced sustainability, with systems increasingly capable of using recycled metal powders and minimizing oxidation waste that plagued earlier technologies.

🏭 Industrial Applications Driving Environmental Impact

While hobbyist 3D printing captures public imagination, the most significant environmental benefits emerge from industrial applications where the technology replaces highly wasteful traditional methods.

Aerospace: Lighter, Stronger, Greener

The aerospace industry has embraced 3D printing enthusiastically, and for good reason. Every kilogram removed from an aircraft saves approximately 3,000 liters of fuel over the aircraft’s lifetime. Additive manufacturing enables the creation of complex, optimized geometries that are both lighter and stronger than traditionally manufactured components.

GE Aviation’s LEAP engine features 3D-printed fuel nozzles that are 25% lighter and five times more durable than their predecessors. Airbus has integrated thousands of 3D-printed parts into its aircraft, reducing weight and fuel consumption while cutting production waste.

Medical Devices: Customization Without Waste

Healthcare applications showcase another environmental advantage: mass customization without the waste typically associated with bespoke manufacturing. Prosthetics, orthotics, dental devices, and surgical guides can be tailored to individual patients without creating unique tooling or generating excessive material waste.

Traditional prosthetic manufacturing involves extensive manual labor, multiple fittings, and significant material waste. 3D printing enables the creation of perfectly fitted devices from digital scans, often in a single production run with minimal waste.

Construction: Building Tomorrow’s Sustainable Structures

3D-printed construction represents one of the most exciting frontiers for environmental impact. Large-scale concrete 3D printers can construct building components or entire structures with significantly less material than traditional construction methods.

These systems optimize material placement, creating structures with strength concentrated where needed and minimal material where it’s not. Construction 3D printing can reduce concrete use by 30-60%, lower construction waste by up to 90%, and dramatically shorten build times—all while reducing the carbon footprint of construction projects.

🌍 Circular Economy: Closing the Loop

3D printing aligns naturally with circular economy principles, where products are designed for longevity, repair, and eventual recycling back into production systems. This represents a fundamental shift from the linear “take-make-dispose” model that has dominated manufacturing.

Failed prints and support structures can be ground down and reprocessed into new filament. Home and industrial recycling systems are becoming more sophisticated and accessible, enabling closed-loop material cycles that previous manufacturing methods couldn’t achieve.

The technology also extends product lifespans by enabling on-demand replacement parts. Instead of discarding an entire product when a single component fails, users can print replacement parts—often from recycled materials—keeping products in service longer and reducing the environmental burden of premature disposal.

📊 Quantifying the Environmental Benefits

While qualitative benefits are clear, quantifying 3D printing’s environmental impact requires careful lifecycle analysis. Research consistently shows positive results, though the magnitude varies by application.

| Environmental Metric | Traditional Manufacturing | 3D Printing | Improvement |

|---|---|---|---|

| Material Waste | 40-90% | 5-10% | 70-90% reduction |

| Energy Consumption (small batch) | High (tooling required) | Low (direct production) | 40-60% reduction |

| Transportation Emissions | High (global supply chains) | Low (local production) | 50-80% reduction |

| Product Weight (optimized designs) | Standard | 15-40% lighter | Lifetime efficiency gains |

These figures represent averages across various studies and applications. Actual results depend heavily on specific use cases, production volumes, and implementation approaches.

⚠️ Challenges and Considerations

Despite its promise, 3D printing isn’t a universal environmental solution. The technology faces legitimate challenges that must be addressed to maximize its green potential.

Production speed remains a limitation for high-volume manufacturing. While 3D printing excels at customization and small batches, traditional mass production methods still prove more energy-efficient per unit for very large production runs. The environmental case for 3D printing strengthens as batch sizes decrease and customization increases.

Material limitations also present challenges. While sustainable materials are expanding, many specialized applications still require conventional plastics or metals. The energy intensity of metal 3D printing, particularly powder bed fusion processes, remains high compared to some traditional metalworking methods.

Post-processing requirements can diminish environmental advantages. Many 3D-printed parts require support removal, surface finishing, or heat treatment that consume additional energy and materials. Ongoing technological improvements are reducing these requirements, but they remain factors in lifecycle assessments.

🚀 Future Horizons: Emerging Technologies

The environmental benefits of 3D printing will only grow as the technology matures. Several emerging developments promise to enhance sustainability further.

Multi-material printing enables the creation of complete products, including electronic components, in single build processes. This eliminates assembly steps and enables new recycling approaches where entire products can be ground down and reprinted.

Bio-printing with living cells and organic materials opens possibilities for growing rather than manufacturing certain products, potentially creating carbon-negative production processes that sequester more carbon than they emit.

AI-optimized design tools are enabling unprecedented material efficiency. Generative design algorithms create structures that use minimal material while meeting or exceeding performance requirements, pushing the boundaries of what’s possible with traditional manufacturing.

💡 Practical Steps Toward Sustainable 3D Printing

Realizing the environmental promise of 3D printing requires conscious choices from manufacturers, businesses, and individual users. Simple practices can significantly enhance sustainability outcomes.

Material selection matters enormously. Choosing bio-based, recycled, or recyclable materials over virgin petroleum-based plastics reduces environmental impact substantially. Many sustainable materials now match or exceed the performance of conventional options.

Design optimization ensures material goes only where needed. Topology optimization software, organic shapes, and lattice structures can reduce material use by 30-50% while maintaining structural integrity.

Implementing in-house recycling systems closes the loop, ensuring failed prints and support material return to production rather than landfills. Desktop recycling solutions have become increasingly affordable and effective.

Energy management, including using renewable energy sources for printing operations and optimizing print schedules to match renewable energy availability, further reduces carbon footprints.

🌟 A Transformative Technology for Sustainable Manufacturing

The environmental promise of 3D printing extends far beyond simple waste reduction. This technology represents a fundamental reimagining of how we design, produce, and distribute physical products in ways that align with ecological sustainability.

From material efficiency to localized production, from circular economy enablement to innovative sustainable materials, additive manufacturing offers tools to address some of manufacturing’s most pressing environmental challenges.

The technology isn’t without limitations or challenges, but the trajectory is clear. As 3D printing matures, as materials science advances, and as adoption accelerates across industries, its role in creating a more sustainable manufacturing ecosystem will only grow more significant.

For businesses, the sustainability benefits increasingly align with economic advantages. Reduced material costs, elimination of tooling expenses, shortened supply chains, and decreased waste disposal costs make environmental responsibility and profitability complementary rather than competing goals.

The revolution in manufacturing that 3D printing enables isn’t just about technology—it’s about rethinking our relationship with material goods, production systems, and the environment. As we face mounting climate challenges and resource constraints, innovations that allow us to create more with less, produce locally rather than globally, and close material loops rather than discarding resources become not just advantageous but essential.

3D printing won’t solve all manufacturing’s environmental challenges, but it provides powerful tools for the transition to sustainable production systems. The technology’s continued evolution, combined with conscious implementation and thoughtful material choices, positions additive manufacturing as a cornerstone of the greener industrial future we urgently need to build.

Toni Santos is a materials researcher and sustainable manufacturing specialist focusing on the development of next-generation biopolymer systems, renewable feedstock cultivation, and the practical innovations driving resource-efficient additive manufacturing. Through an interdisciplinary and science-driven approach, Toni investigates how natural organisms can be transformed into functional materials — across filament chemistry, bio-based composites, and closed-loop production systems. His work is grounded in a fascination with algae not only as lifeforms, but as carriers of industrial potential. From algae filament research to bio-resin development and durable low-energy prints, Toni uncovers the material and engineering pathways through which sustainable practices reshape the future of digital fabrication. With a background in material science and sustainable manufacturing, Toni blends polymer analysis with renewable biomass research to reveal how natural resources can be harnessed to reduce carbon footprint, improve durability, and enable circular production. As the creative mind behind Veltrynox, Toni curates biofilament innovations, low-impact printing methods, and material strategies that advance the ecological integration of 3D printing, biopolymers, and renewable manufacturing systems. His work is a tribute to: The renewable potential of Algae Filament Research and Cultivation The transformative chemistry of Bio-Resin Development and Biocomposites The engineering resilience of Durable Low-Energy Print Systems The sustainable future of Eco-Friendly 3D Printing and Green Manufacturing Whether you're a materials innovator, sustainability engineer, or curious explorer of renewable manufacturing, Toni invites you to discover the transformative power of bio-based materials — one layer, one filament, one sustainable print at a time.