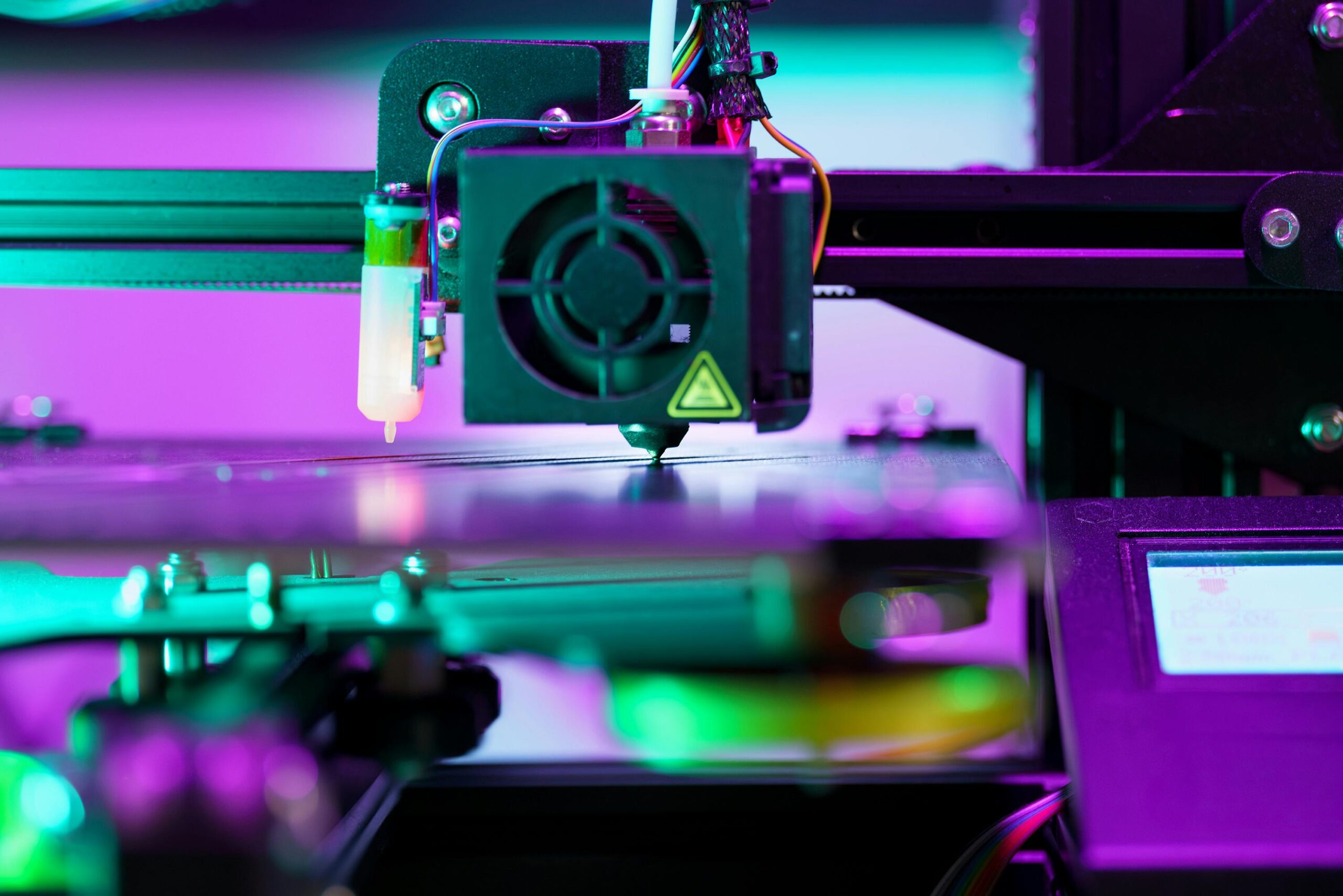

Bio-resin 3D printing has transformed the maker world, but raw prints rarely showcase their true potential without proper post-processing techniques.

Whether you’re creating miniatures, jewelry, prototypes, or functional parts, the finishing touches you apply after printing can mean the difference between amateur-looking objects and professional-grade creations. Bio-resins offer unique environmental advantages over traditional petroleum-based resins, but they also present distinct challenges and opportunities in post-processing workflows.

Understanding how to work with these plant-based materials requires specialized knowledge that goes beyond standard resin finishing techniques. The molecular structure of bio-resins responds differently to solvents, curing processes, and surface treatments compared to their conventional counterparts. This comprehensive guide will walk you through every stage of the post-processing journey, from the moment your print finishes to the final polish that makes your creation shine. ✨

Understanding Bio-Resin Properties Before Post-Processing

Before diving into techniques, recognizing the fundamental characteristics of bio-resins is essential for success. Plant-based resins derived from soy, corn, or other renewable sources have different mechanical and chemical properties than standard photopolymer resins. These differences directly impact how they respond to cleaning, curing, and finishing processes.

Bio-resins typically exhibit slightly greater flexibility and impact resistance when properly processed, making them excellent for functional prints. However, they can be more sensitive to temperature fluctuations during post-processing and may require adjusted curing times to achieve optimal hardness. The polymerization process continues after printing, meaning your workflow timing becomes crucial for achieving consistent results.

Most bio-resins contain natural oils and organic compounds that affect surface adhesion properties. This characteristic influences primer selection, paint compatibility, and bonding strength when assembling multi-part prints. Understanding these molecular-level interactions helps you anticipate challenges and select appropriate materials for each finishing step.

The Critical First Step: Proper Print Removal and Initial Cleaning 🧼

The post-processing journey begins the moment you remove your print from the build plate. Rushing this stage risks damaging delicate features or introducing stress fractures that compromise structural integrity. Allow bio-resin prints to drain for 30-60 seconds while still on the build plate, giving excess uncured resin time to flow back into the vat.

Use a flexible metal scraper at a low angle to gently lift prints from the build plate, working from corner to corner rather than attempting to pry from one edge. Bio-resins can be slightly more elastic than traditional resins, so patience prevents stretching or warping during removal. For particularly delicate prints, warming the build plate to around 40°C (104°F) can soften the bond without affecting print quality.

Initial cleaning removes uncured resin from all surfaces, a step absolutely critical for bio-resins due to their organic composition. Uncured bio-resin left on surfaces can remain tacky indefinitely and may develop biological growth if not properly removed. Use isopropyl alcohol (IPA) at 90% concentration or higher, submerging prints for 3-5 minutes with gentle agitation.

Alternative Eco-Friendly Cleaning Solutions

Given the sustainable nature of bio-resins, many makers prefer environmentally friendly cleaning alternatives to IPA. Plant-based cleaning solutions specifically formulated for resin printing offer comparable results without harsh fumes or environmental impact. These cleaners often work more effectively with bio-resins due to similar organic molecular structures.

Ultrasonic cleaners dramatically improve cleaning efficiency regardless of solution choice. The cavitation process reaches into microscopic details and hollow areas that manual cleaning might miss. For bio-resin prints, use 3-5 minute cycles at medium frequency settings to avoid damaging fine features while ensuring complete resin removal.

UV Curing Optimization for Bio-Resin Materials ☀️

Post-cure processing represents one of the most critical stages for achieving maximum strength and durability in bio-resin prints. Unlike standard resins, bio-resins often require carefully calibrated UV exposure to reach their full mechanical potential without over-curing, which can cause brittleness or discoloration.

The optimal curing time varies significantly between bio-resin formulations, typically ranging from 5-15 minutes depending on print thickness and resin composition. Start with manufacturer recommendations but conduct your own testing with sample pieces to identify the sweet spot for your specific workflow. Over-curing bio-resins can lead to yellowing and reduced flexibility, while under-curing leaves prints weak and prone to deformation.

Temperature control during UV curing significantly impacts final properties. Bio-resins cure most effectively at temperatures between 40-60°C (104-140°F), which accelerates the polymerization process while preventing thermal stress. Many commercial UV curing stations include built-in heating elements, but DIY setups can incorporate heating pads or warm water baths to achieve similar results.

DIY vs. Commercial Curing Solutions

Commercial curing stations offer controlled environments with calibrated UV wavelengths, turntables for even exposure, and temperature regulation. These features provide consistency that’s difficult to replicate with homemade solutions. However, budget-conscious makers can achieve excellent results with DIY setups using UV LED strips, reflective chambers, and basic turntables.

For bio-resins specifically, ensure your curing solution provides wavelengths in the 395-405nm range, matching the photoinitiators used in most plant-based formulations. Multiple shorter curing sessions with cooling periods between often produce better results than single extended exposures, allowing heat to dissipate and preventing thermal degradation of organic compounds.

Support Removal Techniques That Preserve Surface Quality

Support structures serve essential functions during printing but removing them without damaging your print requires strategic technique. Bio-resins’ slightly higher flexibility compared to standard resins can work to your advantage here, as supports often snap away more cleanly with less risk of breaking delicate features.

Remove supports immediately after the first cleaning stage, before UV curing fully hardens the material. At this point, bio-resin maintains enough flexibility to absorb stress without cracking while support connection points remain relatively weak. Use flush cutters positioned parallel to the print surface, cutting as close as possible without touching the main body.

For prints with extensive supports or in difficult-to-reach areas, work systematically from largest to smallest supports. Remove major structural supports first, then progressively tackle finer supports. This approach prevents larger supports from breaking away unexpectedly and damaging adjacent areas. Always cut rather than twist or pull, which can leave marks or create stress concentrations.

Advanced Support Removal Tools

Specialized tools elevate support removal from frustrating chore to precise operation. Precision hobby knives with sharp, replaceable blades allow controlled trimming of support remnants without gouging surrounding surfaces. Dental picks and scrapers provide access to recessed areas where conventional tools can’t reach effectively.

For particularly stubborn support connections, brief exposure to gentle heat from a hair dryer (on low setting) can soften the interface just enough to facilitate cleaner separation. This technique works especially well with bio-resins due to their thermoplastic characteristics, but requires careful temperature control to avoid warping thin features.

Surface Finishing: From Rough to Remarkable 🎨

Transforming a freshly cured print into a smooth, professional-looking piece requires progressive refinement through multiple finishing stages. Bio-resins respond exceptionally well to surface treatments, often achieving glass-like finishes more easily than petroleum-based alternatives due to their slightly softer surface characteristics.

Begin with visible layer lines and support marks using 400-grit sandpaper, working with consistent pressure in circular motions. Progress through increasingly fine grits—600, 800, 1000, and 1500—spending adequate time at each level to remove scratches from the previous stage. Bio-resins sand differently than standard resins, producing less dust and clogging sandpaper more quickly, so keep fresh sheets handy.

Wet sanding with 1000-grit and finer papers dramatically improves results while reducing dust exposure. The water lubricates the sanding process and prevents heat buildup that could soften bio-resin surfaces. For curved or complex surfaces, sanding sponges conform better than paper sheets, providing more even pressure distribution across irregular geometries.

Chemical Smoothing and Vapor Treatments

Chemical smoothing techniques offer alternatives to extensive sanding for certain applications. While acetone vapor smoothing works for some petroleum-based resins, bio-resins typically don’t respond to acetone in the same way. Instead, consider specialized smoothing agents designed for plant-based polymers, though always test on scrap pieces first.

Clear coating after initial finishing provides protection and enhances visual appeal. Bio-resins accept most spray lacquers, epoxy coatings, and polyurethane finishes, though water-based options often bond more reliably with the organic molecular structure. Apply multiple thin coats rather than single thick applications, allowing proper drying time between layers to prevent cloudiness or surface imperfections.

Painting and Coloring Strategies for Bio-Resins

Bio-resin surfaces accept paint readily when properly prepared, opening creative possibilities limited only by imagination. The key to durable, professional-looking paint jobs lies in proper priming and paint selection that complements bio-resin chemistry. Standard acrylic primers work well, but primers specifically formulated for flexible substrates provide superior adhesion and flexibility.

Apply primer in light, even coats using either airbrush or spray can methods. Bio-resins’ slightly porous surface structure absorbs primer effectively, creating an ideal foundation for subsequent paint layers. Allow primer to fully cure—typically 24 hours for maximum adhesion—before applying base colors or detail work.

Acrylic hobby paints remain the most versatile choice for bio-resin painting, offering vibrant colors, easy cleanup, and excellent coverage. The water-based nature of acrylics bonds particularly well with bio-resin surfaces, creating durable finishes that resist chipping and flaking. For metallic effects, consider alcohol-based metallic paints which create more realistic metal appearances than traditional acrylics.

Advanced Painting Techniques and Weathering Effects

Taking painted bio-resin pieces to the next level involves layered painting techniques, washes, and weathering effects. Thin paint washes flow into recessed details, creating depth and visual interest that flat colors cannot achieve. Mix paint with water or specialized acrylic medium at roughly 10:1 ratios, applying with soft brushes and allowing capillary action to draw pigment into crevices.

Dry brushing highlights raised details and creates texture on flat surfaces. Load a stiff brush with undiluted paint, then remove most of it on paper towels before lightly sweeping across surfaces. Only the highest points catch paint, creating subtle highlighting that adds dimension and realism to miniatures, terrain pieces, or decorative objects.

Assembly and Bonding Multi-Part Bio-Resin Prints 🔧

Complex projects often require joining multiple printed components into cohesive assemblies. Bio-resins bond reliably with cyanoacrylate (CA) glues, epoxy adhesives, and UV-curing bonding resins. Each adhesive type offers distinct advantages depending on application requirements and working preferences.

Standard CA glue (super glue) provides fast bonding with excellent strength for most applications. Apply small amounts to both surfaces, press together firmly, and hold for 15-30 seconds. CA accelerator spray speeds curing to near-instant levels but can create brittle bonds if over-applied. For maximum strength, lightly roughen mating surfaces with 400-grit sandpaper before applying adhesive.

Two-part epoxy adhesives offer superior gap-filling properties and longer working times than CA glue. These characteristics make epoxy ideal for joints requiring alignment adjustment or assemblies with slight fit imperfections. Mix epoxy thoroughly according to manufacturer ratios, apply to both surfaces, and allow full cure time—typically 24 hours—before stressing joints.

Magnetic Connections and Mechanical Fasteners

For assemblies requiring disassembly or component swapping, embedding magnets during post-processing creates elegant solutions. Small neodymium magnets fit into pre-designed cavities or drilled holes, bonded in place with CA glue or epoxy. This approach works brilliantly for modular terrain, swappable miniature accessories, or display pieces with interchangeable elements.

Mechanical fasteners like small screws provide robust connections for functional parts subjected to stress or repeated assembly cycles. Bio-resins hold threads reasonably well, especially when heat-set brass inserts are installed. These threaded inserts provide metal threads in plastic parts, dramatically increasing joint durability and cycle life compared to threads cut directly into printed material.

Troubleshooting Common Bio-Resin Post-Processing Challenges

Even experienced makers encounter occasional issues during post-processing workflows. Understanding common problems and their solutions saves time, materials, and frustration. Bio-resins present some unique challenges that differ from traditional photopolymer resins, requiring adjusted approaches and techniques.

Persistent surface tackiness after curing typically indicates incomplete polymerization from insufficient UV exposure or contamination with uncured resin. Thoroughly clean affected pieces again in fresh IPA or cleaning solution, then extend curing time by 3-5 minutes. If tackiness persists, the issue may stem from under-exposure during printing or resin that has exceeded its shelf life.

Warping or deformation during post-processing usually results from uneven curing or excessive heat exposure. Ensure UV light reaches all surfaces equally by rotating prints during curing cycles. If warping occurs, gently warming the piece and applying corrective pressure while it cools can sometimes restore proper geometry, though success depends on severity and print geometry.

Addressing Discoloration and Yellowing

Bio-resins can develop yellow tints from over-curing, prolonged UV exposure, or oxidation of organic compounds. Minimize this issue by curing only as long as necessary to achieve full strength and storing finished prints away from direct sunlight. Clear UV-protective coatings help preserve color integrity in pieces destined for display in naturally lit environments.

If discoloration occurs, light surface sanding followed by clear coating can often mask the issue. For severe yellowing in unpainted pieces, carefully assess whether additional sanding to remove affected surface layers is feasible without compromising fine details or dimensional accuracy.

Maximizing Longevity: Storage and Maintenance of Finished Prints 📦

Proper care after post-processing ensures bio-resin creations maintain their appearance and structural integrity for years. While fully cured bio-resins demonstrate excellent stability, some simple precautions prevent degradation and preserve your hard work indefinitely.

Store finished prints away from prolonged direct sunlight exposure, which can gradually degrade organic compounds and cause color shifts over extended periods. Display cases with UV-filtering glass or acrylic provide ideal protection for showcase pieces while allowing full visibility. For stored prints not on display, opaque containers in climate-controlled environments offer maximum protection.

Temperature stability matters more for bio-resins than petroleum-based alternatives due to their organic composition. Avoid storage locations subject to extreme temperature swings or sustained high heat, which can cause gradual softening or dimensional changes. Room temperature conditions between 18-24°C (64-75°F) with moderate humidity levels provide ideal long-term storage environments.

Regular gentle dusting with soft brushes maintains appearance without risking surface damage. For deeper cleaning of finished painted or coated pieces, slightly damp microfiber cloths work safely without introducing scratching or solvent damage. Avoid harsh cleaners or abrasive materials that might compromise protective coatings or painted surfaces.

Elevating Your Results Through Workflow Refinement

Mastering bio-resin post-processing represents an ongoing journey rather than a destination. Each project provides opportunities to refine techniques, experiment with new approaches, and develop intuitive understanding of how these sustainable materials respond to various treatments. Documentation proves invaluable—maintain a processing journal noting specific techniques, timing, and results for different resin formulations and project types.

The investment in proper post-processing tools and materials pays dividends in both efficiency and quality. While basic finishing can be accomplished with minimal equipment, strategic upgrades to key tools dramatically improve results and reduce time investment. Prioritize tools that address your specific pain points or most frequently encountered challenges in your typical workflow.

Community knowledge-sharing accelerates learning and exposes you to innovative techniques you might never discover independently. Online maker communities, local 3D printing groups, and specialized forums dedicated to resin printing provide invaluable resources for troubleshooting, inspiration, and technique refinement. Don’t hesitate to share your own discoveries—contributing back strengthens the entire community.

Bio-resin technology continues evolving rapidly, with manufacturers regularly introducing improved formulations with enhanced properties and easier post-processing characteristics. Stay informed about new releases and developments in the bio-resin space, as tomorrow’s materials may offer breakthrough capabilities that transform your creative possibilities. The intersection of sustainable materials and advanced manufacturing represents an exciting frontier where environmental responsibility meets unlimited creative potential. 🌱

By implementing these comprehensive post-processing strategies, your bio-resin prints will consistently achieve professional-grade results that showcase both the technology’s capabilities and your developing expertise. Remember that excellence emerges from patient practice, thoughtful experimentation, and willingness to learn from both successes and setbacks along your making journey.

Toni Santos is a materials researcher and sustainable manufacturing specialist focusing on the development of next-generation biopolymer systems, renewable feedstock cultivation, and the practical innovations driving resource-efficient additive manufacturing. Through an interdisciplinary and science-driven approach, Toni investigates how natural organisms can be transformed into functional materials — across filament chemistry, bio-based composites, and closed-loop production systems. His work is grounded in a fascination with algae not only as lifeforms, but as carriers of industrial potential. From algae filament research to bio-resin development and durable low-energy prints, Toni uncovers the material and engineering pathways through which sustainable practices reshape the future of digital fabrication. With a background in material science and sustainable manufacturing, Toni blends polymer analysis with renewable biomass research to reveal how natural resources can be harnessed to reduce carbon footprint, improve durability, and enable circular production. As the creative mind behind Veltrynox, Toni curates biofilament innovations, low-impact printing methods, and material strategies that advance the ecological integration of 3D printing, biopolymers, and renewable manufacturing systems. His work is a tribute to: The renewable potential of Algae Filament Research and Cultivation The transformative chemistry of Bio-Resin Development and Biocomposites The engineering resilience of Durable Low-Energy Print Systems The sustainable future of Eco-Friendly 3D Printing and Green Manufacturing Whether you're a materials innovator, sustainability engineer, or curious explorer of renewable manufacturing, Toni invites you to discover the transformative power of bio-based materials — one layer, one filament, one sustainable print at a time.