3D printing has transformed from a niche technology into a mainstream manufacturing method, but success hinges on understanding the critical relationship between temperature control and material behavior.

🔥 Why Temperature Management Makes or Breaks Your 3D Prints

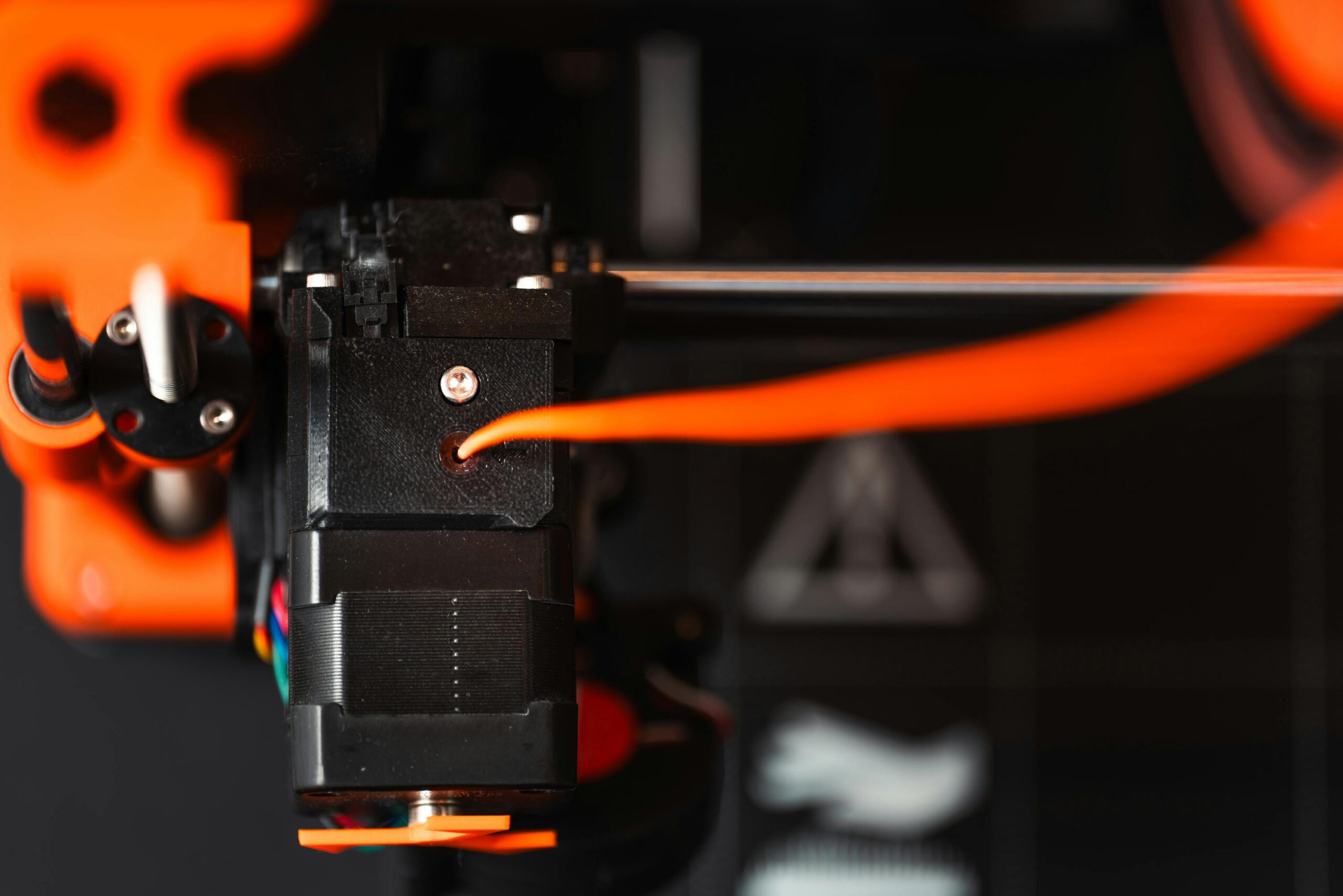

Temperature control stands as the cornerstone of successful 3D printing. Whether you’re working with PLA, ABS, PETG, or exotic filaments, understanding thermal behavior determines the difference between flawless prints and frustrating failures. The extrusion process demands precise heat management across multiple components: the hot end, heated bed, and ambient environment all play crucial roles in achieving optimal layer adhesion and dimensional accuracy.

Every thermoplastic material has a specific temperature window where it transitions from solid to workable viscosity. Too cold, and the filament won’t flow properly through the nozzle, causing clogs and under-extrusion. Too hot, and you’ll encounter stringing, oozing, and potential material degradation. This delicate balance requires both theoretical knowledge and practical experimentation to master.

Understanding the Science Behind Filament Thermal Properties

Each 3D printing filament possesses unique thermal characteristics determined by its polymer composition. The glass transition temperature (Tg) represents the point where a polymer shifts from rigid to rubbery state, while the melting temperature indicates complete material flow. These properties fundamentally influence your printing parameters and final part quality.

PLA, the most beginner-friendly material, features a lower glass transition temperature around 60°C and melts between 180-220°C. This relatively low temperature requirement makes it energy-efficient and less prone to warping. ABS operates at higher temperatures, with a glass transition around 105°C and optimal printing temperatures between 220-250°C, demanding better thermal management systems.

The Critical Role of Heat Transfer in Layer Bonding

Layer adhesion depends entirely on thermal fusion between successive layers. When hot filament deposits onto a previous layer, heat transfers into the substrate, temporarily re-softening it. This creates a molecular bond as polymer chains interdiffuse across the boundary. Insufficient temperature results in weak interlayer adhesion, producing parts that delaminate under stress.

The thermal mass of your print also affects cooling rates. Larger objects retain heat longer, while thin walls and small features cool rapidly. This variation necessitates dynamic temperature management throughout the printing process, sometimes requiring different settings for different geometries within the same print.

📊 Optimal Temperature Ranges for Common Filament Types

Establishing baseline temperature ranges provides a starting point for calibration. However, remember that specific brands and formulations vary significantly, requiring individual testing even within the same material category.

| Filament Type | Nozzle Temperature (°C) | Bed Temperature (°C) | Print Speed (mm/s) |

|---|---|---|---|

| PLA | 190-220 | 50-60 | 40-80 |

| PETG | 220-250 | 70-85 | 30-60 |

| ABS | 220-250 | 95-110 | 40-70 |

| TPU | 210-230 | 40-60 | 15-35 |

| Nylon | 240-270 | 70-90 | 30-50 |

| ASA | 230-260 | 90-105 | 40-70 |

Fine-Tuning Temperature Settings Through Testing

Generic temperature ranges serve as starting points, but optimal settings require systematic testing. Temperature towers represent the gold standard for calibration, printing a vertical structure with different temperature zones. This single print reveals stringing tendencies, layer adhesion quality, overhangs performance, and bridging capabilities across your temperature spectrum.

Begin at the manufacturer’s recommended midpoint temperature and print a tower decreasing by 5°C increments. Examine each section for surface finish quality, layer bonding strength, and defect presence. The optimal temperature typically shows minimal stringing, smooth surfaces, and strong layer adhesion without visible separation when attempting to break the tower sections.

The Heated Bed Temperature Equation

Bed temperature profoundly impacts first-layer adhesion and warping prevention. When hot plastic contacts a cold surface, rapid cooling causes contraction, pulling corners upward and destroying bed adhesion. A heated bed maintains temperature closer to the material’s glass transition point, minimizing thermal stress during initial layers.

Different materials demand vastly different bed temperatures based on their thermal expansion coefficients. PLA’s minimal warping allows printing on beds as cool as 50°C or even room temperature with proper adhesion aids. ABS’s significant thermal contraction requires bed temperatures approaching 110°C to prevent warping on larger prints.

Advanced Bed Temperature Strategies

Static bed temperatures work adequately for most prints, but advanced techniques employ dynamic temperature control. Starting with higher bed temperatures (5-10°C above normal) for the first 3-5 layers improves initial adhesion. Reducing temperature after establishing the foundation decreases overall print time while maintaining dimensional accuracy.

Multi-zone heated beds, found in premium printers, enable localized temperature control. This technology proves particularly valuable for large prints where peripheral areas cool faster than central regions, allowing temperature compensation that prevents differential warping across the build plate.

🌡️ Environmental Temperature and Its Hidden Impact

Ambient temperature significantly affects print quality, especially with temperature-sensitive materials like ABS and ASA. Cold environments create steep thermal gradients between deposited material and surrounding air, exacerbating warping and layer delamination. Professional print farms maintain controlled ambient temperatures between 20-25°C for consistent results.

Enclosed printers create stable thermal environments, trapping heat radiating from the heated bed and hot end. This passive heating raises chamber temperatures naturally, reducing thermal shock and improving print quality with engineering-grade materials. For open-frame printers, adding enclosures dramatically improves success rates with challenging materials.

Managing Drafts and Air Currents

Unexpected air currents from HVAC systems, open windows, or cooling fans can create localized cold zones that ruin prints. Even gentle drafts affect cooling rates asymmetrically, producing warping and dimensional inaccuracies. Position your printer away from ventilation sources and consider directional shields for sensitive prints.

Part cooling fans require careful management. While PLA benefits from aggressive cooling for overhang quality and bridging, materials like ABS and ASA need minimal cooling to prevent layer delamination. Many slicers allow programmatic fan control, ramping cooling gradually or disabling it for initial layers while enabling it for complex geometries later in the print.

Troubleshooting Temperature-Related Print Defects

Recognizing temperature-related defects helps diagnose and correct printing problems efficiently. Stringing, those unwanted plastic threads between print sections, typically indicates excessive nozzle temperature or insufficient retraction. Reducing temperature by 5°C increments often eliminates stringing while maintaining layer adhesion.

Under-extrusion manifests as gaps between perimeters or thin, weak walls. While often attributed to flow rate or extruder issues, insufficient nozzle temperature commonly causes this problem. The filament doesn’t melt completely, increasing back-pressure that prevents consistent extrusion. Increasing temperature restores proper flow characteristics.

Identifying Overheating Symptoms

Excessive temperature produces distinct visual indicators. Drooping overhangs, excessive oozing from the nozzle during travel moves, and darkened or burnt-looking filament suggest overheating. Material degradation occurs when temperatures significantly exceed recommended ranges, breaking down polymer chains and releasing potentially harmful fumes.

Blobs and zits appearing randomly on print surfaces often result from temperature fluctuations. Inconsistent heating causes pressure variations inside the hot end, producing irregular extrusion. Upgrading to PID-tuned temperature control eliminates these fluctuations, maintaining rock-solid temperature stability throughout the print.

⚙️ Advanced Temperature Control Technologies

Modern 3D printers employ sophisticated temperature control systems beyond simple thermistors and heating elements. PID (Proportional-Integral-Derivative) controllers constantly adjust heating power based on real-time temperature measurements, maintaining setpoints within ±1°C. Proper PID tuning dramatically improves print quality by eliminating temperature oscillations.

All-metal hot ends unlock higher temperature capabilities, enabling printing with engineering materials like polycarbonate, nylon, and carbon-fiber composites. PTFE-lined hot ends limit maximum temperatures to approximately 240°C before the liner degrades, while all-metal designs safely reach 300°C and beyond.

Thermistor Calibration and Accuracy

Temperature sensors gradually drift from calibration, producing inaccurate readings that compromise print quality. Annual verification using a temperature calibration rig or thermal camera ensures your printer displays actual temperatures. Even 10°C discrepancies significantly impact results, explaining mysterious print quality degradation over time.

Different thermistor types (NTC 3950, PT100, Type K thermocouples) offer varying accuracy levels and temperature ranges. Upgrading to PT100 or thermocouple sensors provides superior accuracy and reliability, particularly beneficial when printing high-temperature engineering materials requiring precise thermal control.

Material-Specific Temperature Considerations

Specialty filaments introduce unique thermal challenges beyond standard plastics. Wood-filled filaments require lower temperatures (180-200°C) to prevent burning the wood particles, which produces unpleasant odors and nozzle clogs. Metal-filled filaments demand hardened steel nozzles and temperatures specific to their metal content and base polymer.

Flexible TPU filaments need surprisingly precise temperature control despite their forgiving reputation. Too hot, and they become excessively fluid, causing feeding problems and stringing. Too cold, and the material won’t bond properly, producing weak, delaminated parts. Most TPU variants perform best in the 215-225°C range with minimal cooling.

Managing Moisture-Sensitive Materials

Hygroscopic materials like nylon, PETG, and PVA absorb atmospheric moisture, which vaporizes during printing, creating bubbles and poor surface quality. Beyond dry storage, these materials often require slightly elevated printing temperatures to compensate for moisture contamination. Proper drying before printing restores optimal thermal behavior and print quality.

Active filament dryers maintain moisture-sensitive materials in ideal condition during printing. These devices continuously remove absorbed water while feeding filament to the printer, eliminating moisture-related defects. For serious users working with engineering-grade materials, filament dryers represent essential investments rather than optional accessories.

🎯 Creating Your Personal Temperature Calibration System

Developing a systematic approach to temperature calibration eliminates guesswork and accelerates troubleshooting. Maintain detailed logs documenting optimal temperatures for each filament brand and color in your inventory. Colors contain different pigment loads affecting thermal properties, sometimes requiring 5-10°C adjustments from the base material.

Standard test prints provide consistent comparison points when evaluating new materials or settings. Benchy, the ubiquitous 3D printer torture test, reveals temperature impacts on overhangs, bridging, and surface quality. Temperature towers specifically target thermal optimization, while retraction tests combine temperature and mechanical settings for comprehensive calibration.

Building a Temperature Reference Library

Photograph and document successful prints alongside their complete temperature profiles. Include nozzle temperature, bed temperature, chamber temperature (if applicable), cooling settings, and ambient conditions. This reference library accelerates future troubleshooting and helps identify patterns when switching between materials or encountering problems.

Digital tools like spreadsheets or dedicated printing logs transform scattered observations into actionable data. Track success rates, failure modes, and optimal settings for each material. Over time, these records reveal patterns invisible during individual prints, guiding equipment upgrades and technique refinements.

The Future of Thermal Management in 3D Printing

Emerging technologies promise revolutionary advances in temperature control. AI-driven systems analyze print progress in real-time, dynamically adjusting temperatures based on geometry, layer time, and thermal imaging data. These intelligent controllers eliminate manual calibration, automatically optimizing settings for each unique print.

Multi-material printing introduces complex thermal challenges as different polymers with vastly different optimal temperatures coexist in single prints. Advanced hot ends with rapid heating and cooling capabilities enable material transitions within seconds, expanding creative possibilities while demanding sophisticated thermal management algorithms.

🚀 Elevating Your Printing Success Through Temperature Mastery

Mastering thermal behavior transforms 3D printing from frustrating trial-and-error into predictable, high-quality manufacturing. Temperature control influences every aspect of the printing process: adhesion, strength, accuracy, surface finish, and reliability. Investing time in understanding these principles and systematically calibrating your specific equipment pays dividends in reduced failures and superior results.

Start with manufacturer recommendations, but recognize them as starting points rather than absolute rules. Your specific printer, environment, and quality expectations require personalized optimization. Temperature towers, test prints, and careful observation reveal optimal settings for your unique circumstances.

The relationship between temperature and print quality extends beyond simple nozzle settings. Bed temperature, ambient conditions, cooling strategies, and material preparation all contribute to thermal management success. Approach temperature calibration holistically, considering how all elements interact rather than optimizing parameters in isolation.

Document your discoveries meticulously. Today’s successful print provides tomorrow’s troubleshooting baseline. Build your knowledge systematically, and you’ll develop intuitive understanding that guides adjustments before problems occur. Temperature mastery separates hobbyists from skilled practitioners, enabling consistent production of professional-quality prints regardless of complexity or material challenges.

Toni Santos is a materials researcher and sustainable manufacturing specialist focusing on the development of next-generation biopolymer systems, renewable feedstock cultivation, and the practical innovations driving resource-efficient additive manufacturing. Through an interdisciplinary and science-driven approach, Toni investigates how natural organisms can be transformed into functional materials — across filament chemistry, bio-based composites, and closed-loop production systems. His work is grounded in a fascination with algae not only as lifeforms, but as carriers of industrial potential. From algae filament research to bio-resin development and durable low-energy prints, Toni uncovers the material and engineering pathways through which sustainable practices reshape the future of digital fabrication. With a background in material science and sustainable manufacturing, Toni blends polymer analysis with renewable biomass research to reveal how natural resources can be harnessed to reduce carbon footprint, improve durability, and enable circular production. As the creative mind behind Veltrynox, Toni curates biofilament innovations, low-impact printing methods, and material strategies that advance the ecological integration of 3D printing, biopolymers, and renewable manufacturing systems. His work is a tribute to: The renewable potential of Algae Filament Research and Cultivation The transformative chemistry of Bio-Resin Development and Biocomposites The engineering resilience of Durable Low-Energy Print Systems The sustainable future of Eco-Friendly 3D Printing and Green Manufacturing Whether you're a materials innovator, sustainability engineer, or curious explorer of renewable manufacturing, Toni invites you to discover the transformative power of bio-based materials — one layer, one filament, one sustainable print at a time.