The fusion of algae-based filaments and FDM 3D printing technology is creating a revolutionary pathway toward sustainable manufacturing, offering eco-conscious makers an unprecedented opportunity to reduce environmental impact.

🌿 The Green Revolution in Additive Manufacturing

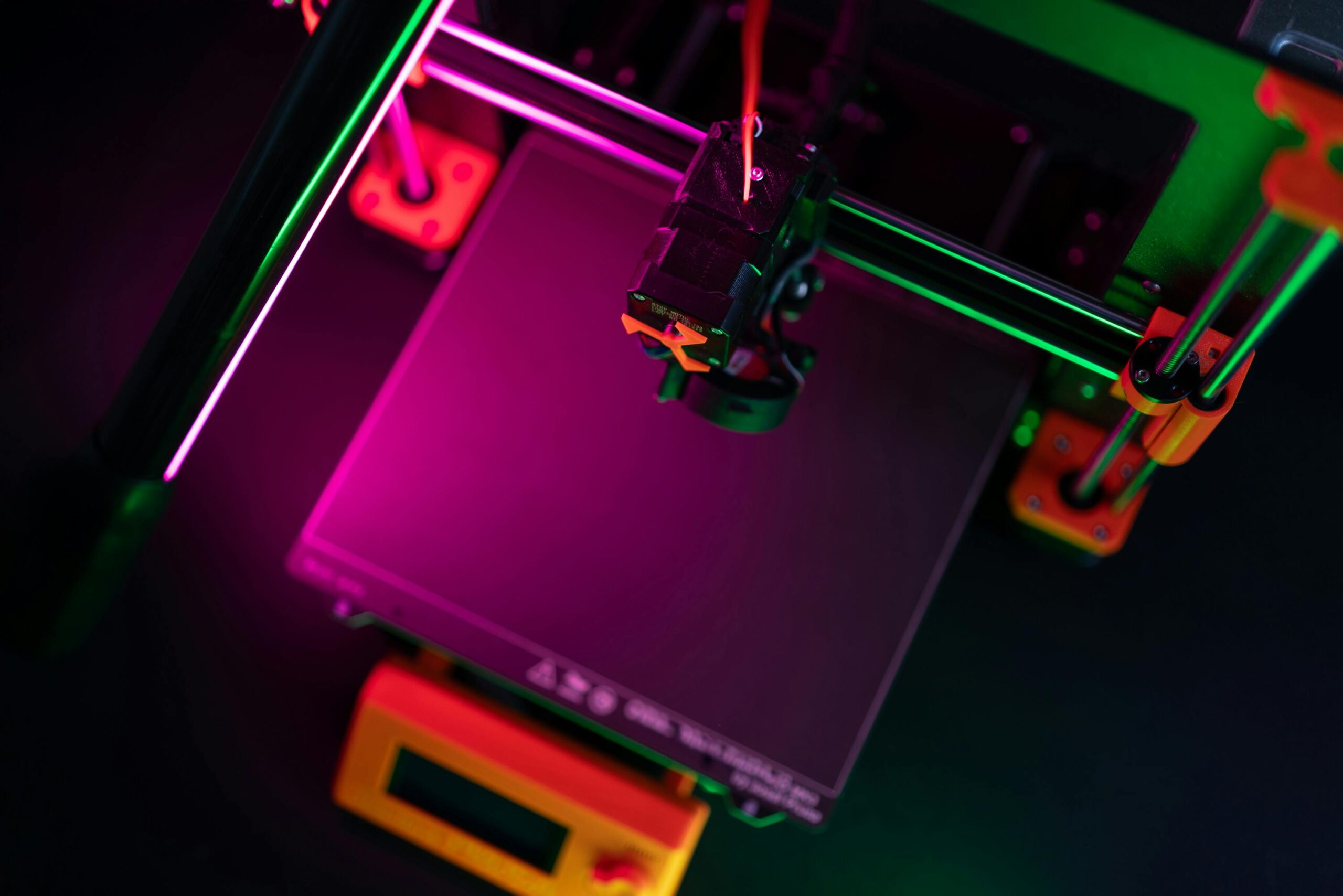

The world of 3D printing stands at a critical crossroads. As environmental concerns intensify and sustainability becomes non-negotiable, the additive manufacturing industry faces mounting pressure to reinvent itself. Traditional plastic filaments, predominantly derived from petroleum-based sources like PLA and ABS, have dominated the FDM (Fused Deposition Modeling) printing landscape for years. However, their environmental footprint tells a troubling story of resource depletion and ecological harm.

Enter algae filament—a game-changing biomaterial that’s transforming how we approach 3D printing. This innovative material harnesses the natural abundance of algae, one of Earth’s most sustainable and rapidly renewable resources, to create printing filament that doesn’t compromise our planet’s future. The marriage between algae-based materials and FDM technology represents more than just an incremental improvement; it’s a fundamental shift in manufacturing philosophy.

Understanding Algae Filament: Nature’s Perfect Printing Material

Algae filament emerges from a sophisticated process that transforms aquatic biomass into printable thermoplastic material. Unlike conventional petroleum-based filaments that require millions of years of fossil fuel formation, algae can be cultivated and harvested in mere weeks. This rapid growth cycle makes algae an exceptionally sustainable feedstock for manufacturing applications.

The composition of algae filament typically combines algae biomass with biodegradable binding polymers, creating a hybrid material that maintains the printability characteristics essential for FDM printing while dramatically reducing environmental impact. Most formulations contain between 20% to 40% algae content, with the remainder consisting of PLA or other biodegradable polymers that ensure proper melting characteristics and layer adhesion.

The Environmental Advantages That Matter

The carbon footprint comparison between traditional and algae-based filaments reveals staggering differences. Algae cultivation actually removes CO2 from the atmosphere through photosynthesis, meaning the raw material production phase creates a net carbon-negative effect. Petroleum-based plastics, conversely, release stored carbon that has been sequestered underground for millennia.

Water usage presents another compelling advantage. Algae thrives in various water conditions, including saltwater and wastewater, eliminating competition with agricultural freshwater demands. Some algae cultivation facilities even integrate with wastewater treatment systems, providing dual environmental benefits by cleaning water while producing biomass for manufacturing.

⚙️ FDM Printers: The Ideal Technology for Algae Filament

Fused Deposition Modeling technology has become the most accessible and widespread 3D printing methodology worldwide. Its straightforward mechanism—heating thermoplastic filament and depositing it layer by layer—makes it perfectly suited for experimenting with novel materials like algae-based filaments.

The beauty of FDM technology lies in its versatility. Unlike resin-based or powder-based printing systems that require specific material chemistries, FDM printers can accommodate a wide range of thermoplastic materials with relatively simple adjustments to temperature settings and print speeds. This flexibility has enabled the algae filament innovation to reach mainstream makers without requiring specialized equipment.

Printer Requirements and Compatibility

Most standard FDM printers can handle algae filament with minimal modifications. The material typically processes at temperatures between 190°C and 220°C—similar to standard PLA filament. This temperature range falls within the capabilities of virtually all consumer and professional FDM machines, from budget-friendly entry-level models to industrial-grade systems.

The key compatibility factors include:

- Standard 1.75mm or 2.85mm filament diameter support

- Hotend capable of reaching 220°C consistently

- Adequate cooling system for proper layer adhesion

- Build surface compatibility (heated beds recommended but not always required)

- Enclosed build chamber beneficial but optional

Printing Parameters: Optimizing Your Algae Filament Experience 🎯

Achieving optimal results with algae filament requires understanding its unique characteristics. While similar to PLA in many respects, the organic content introduces variables that demand attention to detail and willingness to experiment.

Temperature Settings That Work

Nozzle temperature typically ranges from 200°C to 215°C, though specific brands may recommend slightly different ranges. Starting at 205°C provides a reliable baseline for most algae filament formulations. The bed temperature should be set between 50°C and 60°C to ensure proper first-layer adhesion without warping.

Print speed considerations differ slightly from conventional PLA. Most users report optimal results between 40mm/s and 60mm/s, slightly slower than typical PLA speeds. This reduced velocity allows the material adequate time to bond between layers, compensating for the organic additives that can affect thermal properties.

Adhesion and Surface Preparation

Algae filament generally exhibits excellent bed adhesion characteristics. A clean glass bed, PEI sheet, or even painter’s tape provides sufficient grip for most prints. Some formulations actually adhere too well, making print removal challenging without proper preparation. Applying a thin layer of glue stick or using release agents can prevent damage to both prints and build surfaces.

🌊 The Science Behind Algae Cultivation for Filament Production

Understanding the source material enriches appreciation for this sustainable innovation. Algae represents one of Earth’s oldest life forms, with species ranging from microscopic phytoplankton to massive kelp forests. For filament production, microalgae strains are typically preferred due to their rapid growth rates and high lipid content.

Cultivation occurs in controlled photobioreactors or open pond systems where conditions are optimized for maximum biomass production. Light exposure, nutrient availability, pH levels, and temperature are carefully managed to accelerate growth. Under ideal conditions, algae biomass can double in as little as 24 hours—a growth rate unmatched by any terrestrial plant.

From Pond to Printer: The Processing Journey

Harvested algae undergoes dewatering, drying, and pulverization to create a fine powder. This algae powder is then blended with biodegradable polymers and processing additives before being extruded into filament. The extrusion process requires precise temperature control and consistent feeding to produce filament with uniform diameter—critical for reliable FDM printing.

Quality control measures ensure filament diameter tolerances remain within ±0.05mm, preventing print failures due to inconsistent extrusion. Moisture content is also carefully controlled, as algae biomass naturally retains water that could compromise print quality if not properly managed.

Real-World Applications and Success Stories 🏆

The practical applications of algae filament extend far beyond theoretical sustainability discussions. Designers, engineers, and artists worldwide are discovering that environmental responsibility doesn’t require performance compromises.

Architecture and construction prototyping benefit from algae filament’s biodegradability. Scale models that traditionally ended up in landfills can now decompose naturally, reducing project environmental footprints. Several architecture firms have adopted algae-based materials for client presentations, using sustainability as a selling point that resonates with environmentally conscious stakeholders.

Consumer Products and Packaging

Product designers are leveraging algae filament for functional prototypes and even small-batch production runs. The material’s aesthetic qualities—often featuring unique natural coloring and subtle texturing—create distinctive products that communicate environmental values visually.

Packaging applications represent particularly promising territory. Custom packaging inserts, protective cases, and display fixtures printed from algae filament offer brands tangible ways to demonstrate sustainability commitments. Unlike greenwashing marketing claims, algae-based products provide verifiable environmental benefits that consumers can see and touch.

Comparing Costs: Investment vs. Impact 💰

Price considerations remain important for widespread adoption. Algae filament currently costs approximately 30% to 60% more than standard PLA filament, reflecting the specialized cultivation and processing infrastructure required. A typical 1kg spool ranges from $35 to $55 compared to $20 to $30 for conventional PLA.

However, cost analysis must consider lifecycle factors beyond initial purchase price. Algae filament’s biodegradability eliminates disposal costs and environmental remediation expenses. For businesses, the marketing value and brand differentiation potential may justify premium pricing, particularly when targeting eco-conscious consumer segments.

| Filament Type | Price per kg | Carbon Footprint | Biodegradability | Recyclability |

|---|---|---|---|---|

| Standard PLA | $20-30 | Moderate | Industrial composting | Limited |

| Algae Filament | $35-55 | Carbon negative | Natural degradation | Compostable |

| ABS Filament | $25-35 | High | No | Yes |

| PETG Filament | $25-40 | High | No | Yes |

🔧 Troubleshooting Common Challenges

Like any emerging technology, algae filament printing presents unique challenges that users must navigate. Understanding these potential issues and their solutions ensures successful printing experiences.

Moisture Management

Algae filament’s organic composition makes it particularly susceptible to moisture absorption. Filament that has absorbed atmospheric humidity will produce prints with surface imperfections, stringing, and poor layer adhesion. Storing filament in airtight containers with desiccant packets prevents moisture-related issues. If moisture contamination occurs, drying filament at 50°C for 4-6 hours in a food dehydrator or specialized filament dryer restores optimal printing conditions.

Clogging Prevention

The particulate nature of algae biomass occasionally causes nozzle clogs, especially with smaller nozzle diameters. Using 0.4mm or larger nozzles minimizes this risk. Regular cold pulls—a cleaning technique involving heating and cooling cycles—keeps nozzles clear. Some users perform preventive cold pulls every 10-15 hours of printing with algae filament.

The Future Landscape: Where Innovation Meets Necessity 🚀

The trajectory of algae filament development points toward exciting possibilities. Research initiatives worldwide are exploring enhanced formulations with improved mechanical properties, expanded color palettes derived from natural pigments, and even functionally enhanced variants incorporating conductive or antimicrobial properties.

Scaling production represents the next critical frontier. As demand increases and production infrastructure expands, economies of scale will drive prices downward, making sustainable options increasingly competitive with conventional materials. Several startups and established filament manufacturers have announced capacity expansion plans, signaling market confidence in algae-based materials.

Integration with Circular Economy Models

The true potential of algae filament emerges within circular economy frameworks. Imagine production systems where printed objects that reach end-of-life are composted, with resulting nutrients feeding algae cultivation that produces the next generation of filament. This closed-loop vision represents manufacturing’s sustainable future—one where waste becomes feedstock and environmental impact approaches zero.

Making the Switch: Practical Steps for Adoption 🌱

Transitioning to algae filament doesn’t require radical equipment changes or extensive retraining. Start by ordering a single spool from reputable suppliers specializing in sustainable materials. Begin with simple geometric prints to familiarize yourself with the material’s behavior before attempting complex projects.

Document your experiences systematically. Record temperature settings, print speeds, and results to build a personal knowledge base. The algae filament community actively shares insights through online forums, social media groups, and maker spaces—leverage these resources to accelerate your learning curve.

Consider the psychological and marketing dimensions beyond technical performance. Prints created from algae filament carry inherent storytelling power. Whether showcasing prototypes to clients or displaying personal creations, the sustainable origin sparks conversations and demonstrates values alignment that resonates in our environmentally conscious era.

Beyond Environmental Impact: The Complete Value Proposition ✨

While sustainability drives initial interest in algae filament, users quickly discover additional benefits. The material’s natural aesthetic qualities create distinctive surface finishes that conventional plastics cannot replicate. Subtle color variations and organic textures impart character that mass-produced plastics lack.

Print quality rivals conventional PLA in most applications, with comparable layer adhesion, dimensional accuracy, and surface finish. Mechanical properties—including tensile strength and flexibility—fall within acceptable ranges for prototyping and many functional applications. The material machines, sands, and finishes similarly to PLA, requiring no specialized post-processing techniques.

The non-toxic nature of algae filament makes it particularly appealing for educational environments and applications involving food contact or children’s products. While specific food-safety certifications depend on formulation and processing, the organic base material eliminates concerns about harmful chemical additives present in some conventional plastics.

🎨 The Creative Dimension: Aesthetics Meet Ethics

Artists and designers are discovering that sustainability and beauty aren’t mutually exclusive. Algae filament’s natural coloring—ranging from deep greens to earthy browns depending on species and processing—creates artwork that visually communicates environmental themes without requiring pigment additives.

Some manufacturers are developing color-varied filaments using different algae species, creating natural palettes unavailable in synthetic materials. These biologically-derived colors possess organic authenticity that resonates with audiences increasingly skeptical of artificial alternatives.

The material also accepts natural dyes and finishing techniques beautifully, allowing further customization while maintaining environmental integrity. Post-processing with plant-based stains, oils, and waxes creates sophisticated finishes that enhance both aesthetics and sustainability credentials.

The Perfect Pairing: Why FDM and Algae Filament Belong Together 🤝

The synergy between FDM technology and algae filament extends beyond mere compatibility. FDM’s accessibility democratizes sustainable manufacturing, placing eco-friendly production capabilities in workshops, classrooms, and homes worldwide. This widespread availability accelerates adoption and normalizes sustainable material choices.

The open-source nature of much FDM technology fosters innovation ecosystems where material developers and printer manufacturers collaborate to optimize performance. Community-driven development accelerates problem-solving and knowledge sharing, reducing barriers that might otherwise slow sustainable material adoption.

As FDM technology continues evolving with improved precision, faster speeds, and larger build volumes, algae filament benefits from these advances. The relationship is mutually reinforcing—better printers improve algae filament performance, while innovative materials like algae filament justify continued FDM technology investment.

The revolution in sustainable 3D printing isn’t coming—it’s already here. Algae filament and FDM printers together represent more than technological advancement; they embody a fundamental shift in how we conceptualize manufacturing’s relationship with our environment. Every print created from algae-based materials demonstrates that sustainability and functionality can coexist, that environmental responsibility enhances rather than constrains creativity, and that the future of making belongs to those who recognize our planet’s limits while embracing innovation’s possibilities. The perfect pairing of algae filament and FDM technology invites us all to participate in manufacturing’s sustainable transformation, one layer at a time.

Toni Santos is a materials researcher and sustainable manufacturing specialist focusing on the development of next-generation biopolymer systems, renewable feedstock cultivation, and the practical innovations driving resource-efficient additive manufacturing. Through an interdisciplinary and science-driven approach, Toni investigates how natural organisms can be transformed into functional materials — across filament chemistry, bio-based composites, and closed-loop production systems. His work is grounded in a fascination with algae not only as lifeforms, but as carriers of industrial potential. From algae filament research to bio-resin development and durable low-energy prints, Toni uncovers the material and engineering pathways through which sustainable practices reshape the future of digital fabrication. With a background in material science and sustainable manufacturing, Toni blends polymer analysis with renewable biomass research to reveal how natural resources can be harnessed to reduce carbon footprint, improve durability, and enable circular production. As the creative mind behind Veltrynox, Toni curates biofilament innovations, low-impact printing methods, and material strategies that advance the ecological integration of 3D printing, biopolymers, and renewable manufacturing systems. His work is a tribute to: The renewable potential of Algae Filament Research and Cultivation The transformative chemistry of Bio-Resin Development and Biocomposites The engineering resilience of Durable Low-Energy Print Systems The sustainable future of Eco-Friendly 3D Printing and Green Manufacturing Whether you're a materials innovator, sustainability engineer, or curious explorer of renewable manufacturing, Toni invites you to discover the transformative power of bio-based materials — one layer, one filament, one sustainable print at a time.